Product Description

We are supplier of S-a-n-y / CHINAMFG / Konecranes / CHINAMFG / Fantuzzi / CVS container reach stacker and empty container handling stacker spare parts.

We also have Volvo engine spare parts and Donaldson filters.

We can supply both genuine and CHINAMFG parts.

If any other inquiries please send to me.

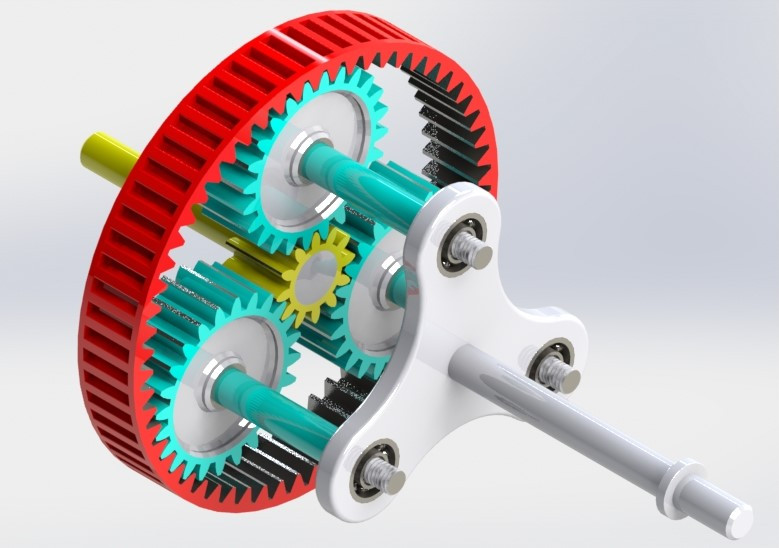

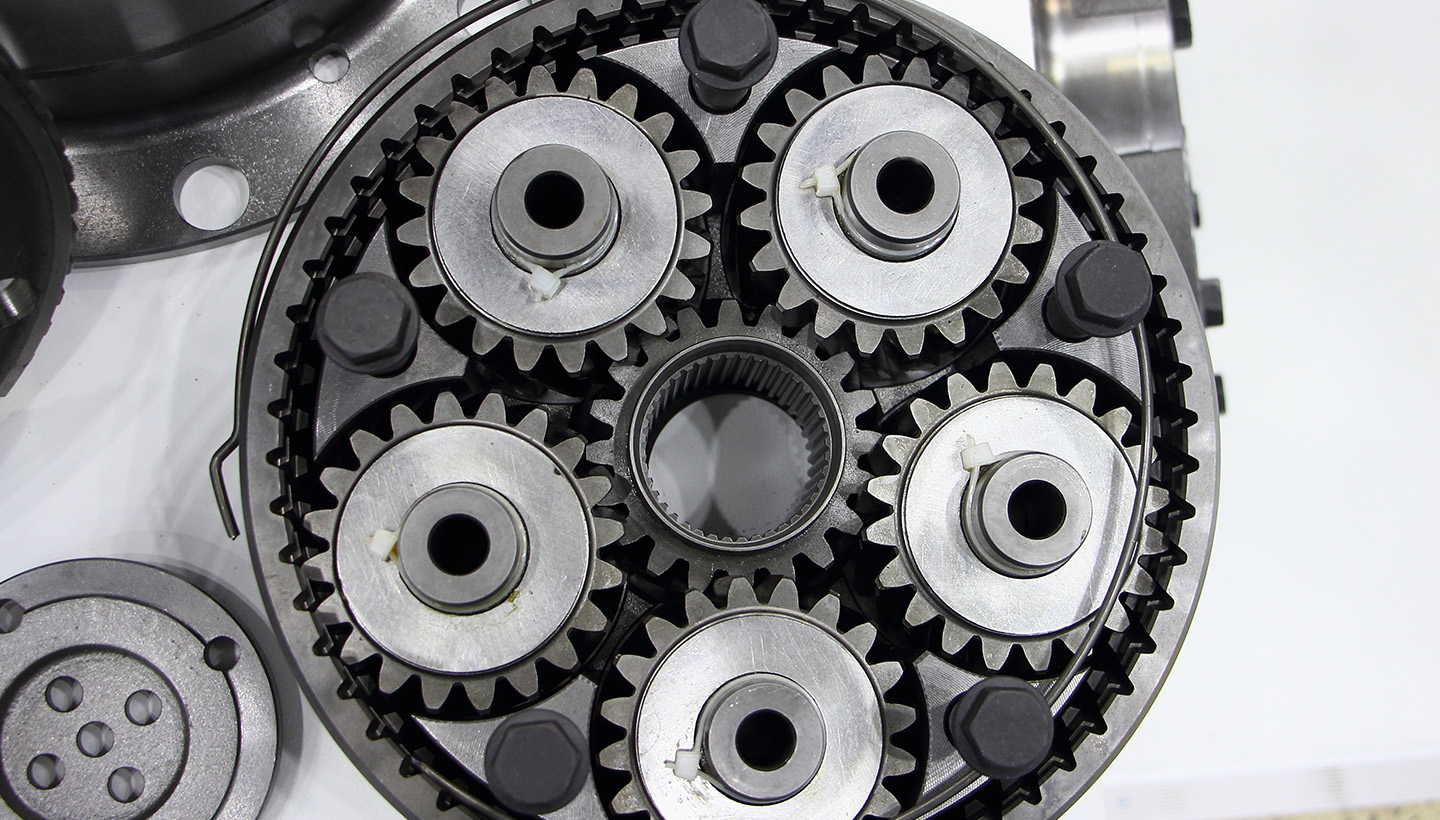

Kalmar Planetary Gear

Joystick

Kalmar Length sensor

DANA Repair kit

Donaldson Filter

Fantuzzi Floating seal

Kalmar Hydraulic pump

Konecranes Potentiometer

Linde Bearing

Parker Solenoid valve

VOLVO Water pump

S-a-n-y / CHINAMFG / Konecranes / CHINAMFG / Fantuzzi / CVS port machinery empty container reach stacker spare parts, Kalmar,Konecranes,S-a-n-y,Linde,Fantuzzi,Dana,Parker,Volvo,TVH,Donaldson,Fleetguard spare parts and so on.

If you need these, please contact me.

Any inquiries about port machinery spare parts, please send to me without hesitation.

| Type: | Bearing |

|---|---|

| Application: | Hoisting Machinery |

| Condition: | New |

| Parts Name 1: | Plate Pressure |

| Parts Name 2: | Hub Nut |

| Parts Name 3: | Adjac End Jumper Implement |

| Customization: |

Available

| Customized Request |

|---|

How do planetary gears handle changes in speed and torque distribution?

Planetary gears are capable of effectively handling changes in speed and torque distribution due to their unique design and configuration. Let’s explore how planetary gears handle these changes:

- Speed Changes:

Planetary gears can handle speed changes by utilizing the different gear ratios they offer. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. When the input speed is applied to the sun gear, it gets transmitted to the planet gears, resulting in a specific output speed. By changing the gear ratio, the output speed can be adjusted accordingly. This ability to vary the gear ratio allows planetary gears to adapt to different speed requirements in mechanical systems.

- Torque Distribution:

Planetary gears excel in distributing torque across multiple gear teeth, ensuring efficient torque transmission and load sharing. The planet gears are meshed with both the sun gear and the ring gear, enabling torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. The load is shared among the planet gears, preventing excessive wear and minimizing the risk of gear failure.

- Torque Amplification:

Planetary gears can also handle torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The arrangement of multiple gear sets in a compact design enables torque amplification, making planetary gears suitable for applications that require high torque output while maintaining a smaller physical size.

- Load Balancing:

Another aspect of torque distribution in planetary gears is load balancing. The planet gears distribute the load across multiple gear teeth, reducing the concentration of forces on individual teeth. This load balancing capability results in improved gear system durability and longevity. It also helps in minimizing vibration, noise, and wear, ensuring smoother and more reliable operation.

- Flexible Configuration:

Planetary gears offer flexibility in their configuration, allowing for the accommodation of changes in speed and torque distribution. The number of planet gears, the size of the gears, and their arrangement can be adjusted to meet specific application requirements. This flexibility enables planetary gears to handle a wide range of speed and torque variations, making them adaptable to different mechanical setups.

In summary, planetary gears handle changes in speed and torque distribution through their ability to adjust gear ratios, distribute torque across multiple gear teeth, amplify torque, balance loads, and accommodate flexible configurations. These characteristics make planetary gears suitable for applications that require precise control over speed and torque, efficient power transmission, and reliable performance.

How do planetary gears contribute to speed reduction and torque amplification?

Planetary gears offer the capability of both speed reduction and torque amplification, making them versatile components in various mechanical systems. Let’s explore how planetary gears achieve these functions:

- Speed Reduction:

Planetary gears can reduce rotational speed by utilizing their gear arrangement. The key elements involved in speed reduction are the sun gear, planet gears, and ring gear. Consider the following scenarios:

- Epicyclic Gear Set:

In a basic planetary gear arrangement, when the sun gear is used as the input and the ring gear is fixed, the planet gears rotate on their own axes while also revolving around the sun gear. This configuration causes the output speed to be lower than the input speed. The reduction in speed is determined by the gear ratios between the sun gear, planet gears, and ring gear.

- Multiple Stages:

Planetary gears can be combined into multiple stages, with each stage having its own set of sun gears, planet gears, and ring gears. By connecting the output of one stage to the input of another, the rotational speed can be further reduced. This allows for greater flexibility in achieving the desired speed reduction in complex mechanical systems.

- Torque Amplification:

Planetary gears are also capable of amplifying torque, enabling them to handle higher loads and provide increased output torque. The torque amplification occurs in the following scenarios:

- Epicyclic Gear Set:

When the sun gear is used as the input and the ring gear is the output, the planet gears rotate on their own axes while also revolving around the sun gear. This arrangement allows for torque amplification, meaning the output torque can be higher than the input torque. The specific torque amplification factor depends on the gear ratios and the number of planet gears in the system.

- Combination of Gear Stages:

By combining multiple stages of planetary gears, torque amplification can be further increased. Each stage contributes to the overall torque amplification, allowing the system to handle even higher loads and transmit greater torque.

In summary, planetary gears contribute to speed reduction by utilizing the gear ratios between the sun gear, planet gears, and ring gear. They achieve torque amplification by utilizing the arrangement of the gears in an epicyclic gear set, as well as through the combination of multiple gear stages. These capabilities make planetary gears valuable in various applications where speed reduction and torque amplification are required, such as automotive transmissions, industrial machinery, and power transmission systems.

Can you describe the role of sun gears, planet gears, and ring gears in planetary systems?

In a planetary gear system, each component—the sun gear, planet gears, and ring gear—plays a crucial role in the overall operation and functionality. Let’s explore the roles of these gears:

- Sun Gear:

The sun gear is a central component in a planetary gear system. It is typically located at the center and is driven by an input source such as a motor or engine. The sun gear receives the input power and transmits it to the other gears in the system. As the sun gear rotates, it drives the rotation of the planet gears, which, in turn, contribute to the overall gear operation. The size and number of teeth on the sun gear determine the gear ratio and torque characteristics of the system.

- Planet Gears:

The planet gears are gears that surround the sun gear in a planetary gear system. They are typically smaller in size compared to the sun gear and are connected to a carrier or arm. The planet gears mesh with both the sun gear and the ring gear. As the sun gear rotates, it drives the rotation of the planet gears. The planet gears exhibit both rotational and orbital motion. While they rotate on their own axes, they also orbit around the sun gear. This combination of rotational and orbital movement allows the planet gears to transmit torque and contribute to the overall gear reduction or amplification. The arrangement and number of planet gears can vary depending on the specific design and requirements of the system.

- Ring Gear:

The ring gear is the outermost gear in a planetary gear system. It has internal teeth that mesh with the planet gears. The ring gear remains fixed or stationary while the sun gear and planet gears rotate. The interaction between the planet gears and the ring gear enables the gear system to achieve gear reduction or amplification. The size and number of teeth on the ring gear also influence the gear ratio and torque characteristics of the system.

In summary, the sun gear serves as the primary driver, receiving the input power and transmitting it to the other gears. The planet gears rotate and orbit around the sun gear, contributing to torque transmission and gear functionality. The ring gear remains fixed and meshes with the planet gears, allowing for gear reduction or amplification. Together, these gears work in harmony to achieve the desired gear ratios, torque transmission, and overall operation of planetary gear systems.

editor by CX 2023-11-02