Product Description

Item:Customized CNC Milling Turning Steel Metal Reduction Starter Shaft Spline Pinion Wheel Transmission Gear Planetary Sun Drive Spur Gear

1. High degree of automation and high production efficiency;

2. Strong adaptability to CNC machining objects. When changing the processing object, in addition to replacing and solving the blank clamping mode, it only needs to be reprogrammed;

3. High machining precision and stable quality. The machining dimensional accuracy is between 0.005 ~ 0.01 mm, which is not affected by the complexity of parts;

Parameter :

| Item | Customized CNC Milling Turning Steel Metal Reduction Starter Shaft Spline Pinion Wheel Transmission Gear Planetary Sun Drive Spur Gear |

| Weight | Customized |

| Dimension | Customized |

| Material | Aluminum alloy(6063 T5,6061,5052,7075,1060…),Stainless steel(316L,304,303…),Copper,Brass,Bronze,Carbon steel,PET,POM,Nylon… |

| Machined Technology | 3,4,5 Axis CNC Machining,CNC Milling,CNC Turning,Laser Cutting,Die Casting,Cold forging,Aluminum Extrusion,Sheet Metal Fabrication,Stamping,Welding,Friction Stir Welding,Assembling. |

| Surface Treatment | Anodizing,Painting,Powder Coating,electrophoresis,Passivation,Sand Blasting,Plating,Blackening,Polishing… |

| Tolerance | ±0.01MM |

| Application | Electronic products body ,Telecom Chasis,Cover,aerospace structure parts,heat sink,aluminum cooling plate,gear&shaft,bearing,high speed feed through,other OEM/ODM customized machining parts |

Our advantage:

1. Experienced engineering team;

2. Full process QC inspection, complete quality system before, during and after processing;

3. Efficient and rapid response, benign interaction between business and production, and accurately grasp customer requirements;

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in high-torque applications?

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

Can you explain the process of gear shifting in planetary gear systems?

Gear shifting in planetary gear systems involves changing the gear ratio by engaging or disengaging specific components of the gear set. Let’s explore the process of gear shifting in more detail:

- Clutching and Braking:

The gear shifting process in planetary gear systems primarily relies on clutching and braking mechanisms. These mechanisms selectively connect or disconnect various gears within the system to achieve the desired gear ratio. Here are the key steps involved:

- Clutch Engagement:

To shift to a higher gear ratio, the clutch associated with the gear component that needs to be engaged is activated. The clutch connects the rotating member, such as the sun gear, planet carrier, or ring gear, to the stationary member, allowing torque transmission. This engagement results in a change in the gear ratio, leading to higher speed or torque output depending on the specific gear set configuration.

- Brake Application:

On the other hand, to shift to a lower gear ratio, a brake associated with the gear component that needs to be disengaged is applied. The brake immobilizes or slows down the rotation of the selected gear element, preventing it from transmitting torque. By selectively braking certain components, the gear ratio is altered, resulting in a lower speed or higher torque output.

- Sequential Shifting:

In some planetary gear systems, gear shifting is performed sequentially. This means that one gear component is engaged or disengaged at a time, gradually transitioning from one gear ratio to another. Sequential shifting allows for smooth and controlled gear changes, minimizing the stress on the transmission components and ensuring seamless power transmission.

- Electronic Control:

In modern applications, gear shifting in planetary gear systems is often electronically controlled. Electronic control systems utilize sensors, actuators, and a control unit to monitor various parameters such as vehicle speed, engine load, and driver input. Based on these inputs, the control unit determines the optimal gear shift points and actuates the clutches and brakes accordingly. Electronic control enhances the efficiency, precision, and automation of the gear shifting process.

In summary, gear shifting in planetary gear systems involves the engagement and disengagement of clutches and brakes to alter the gear ratio. By selectively connecting or disconnecting specific gear components, the speed and torque output can be adjusted. Sequential shifting and electronic control systems further enhance the gear shifting process, providing smooth and efficient operation in various applications, including automotive transmissions and industrial machinery.

How do planetary gears differ from other types of gear arrangements?

Planetary gears, also known as epicyclic gears, possess unique characteristics and differ from other types of gear arrangements in several ways. Let’s explore the distinguishing features of planetary gears:

- Internal Gear Meshing:

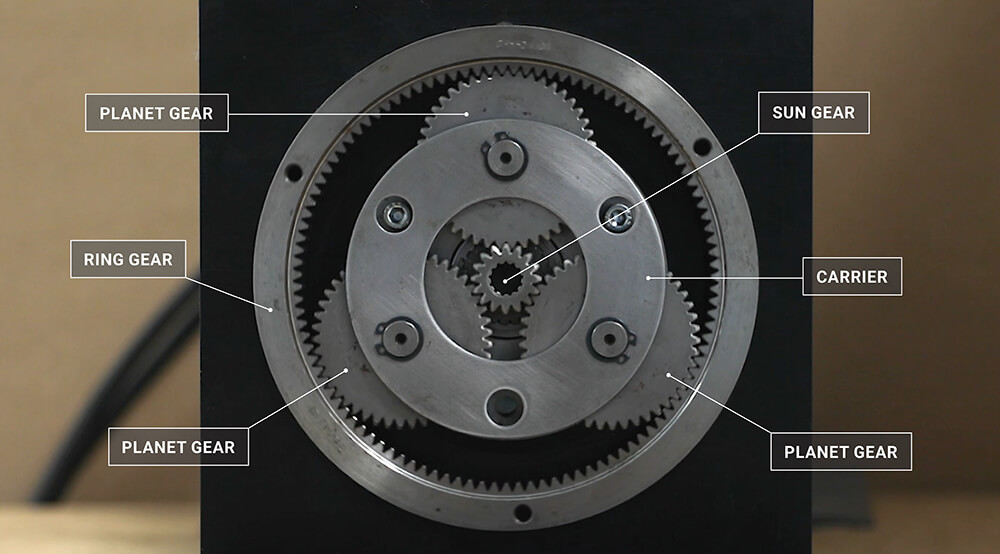

Unlike other gear arrangements where the gears typically mesh externally, planetary gears have internal gear meshing. This means that the gear teeth of the sun gear, planet gears, and ring gear are located on the inside surfaces, allowing for compact and space-efficient designs.

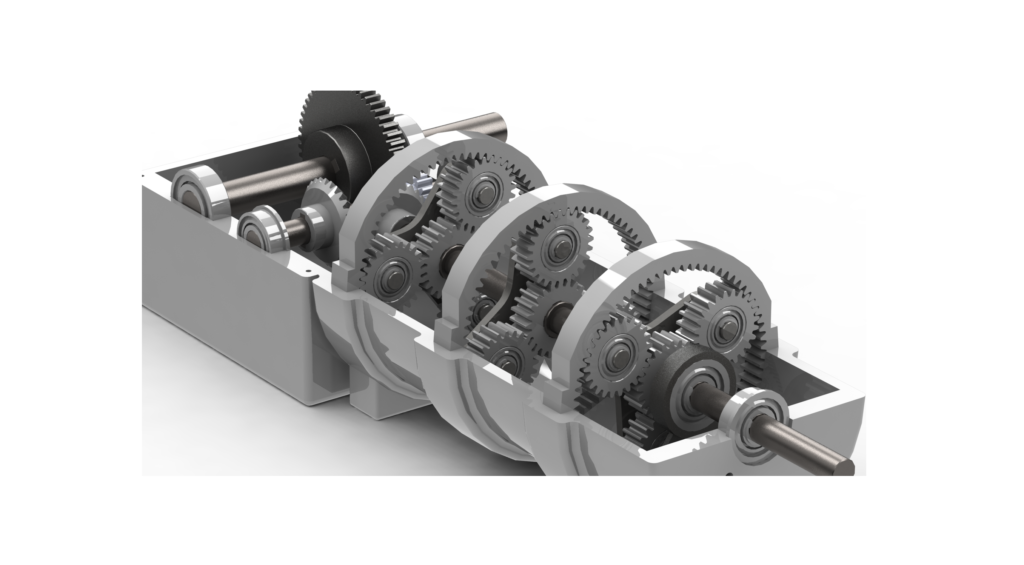

- Multiple Gear Sets:

Planetary gear systems consist of multiple gear sets working in parallel or series. These gear sets include the sun gear, planet gears, and ring gear. By combining and configuring these gear sets, different gear ratios and torque distributions can be achieved, providing versatility and flexibility in various applications.

- Central Sun Gear:

A distinctive feature of planetary gears is the presence of a central sun gear. The sun gear is typically driven by an input source, such as a motor or engine. It is located at the center of the gear arrangement and serves as the primary driver for overall gear operation.

- Orbiting Planet Gears:

In planetary gears, the planet gears rotate on their own axes while simultaneously orbiting around the sun gear. This combination of rotational and orbital movement allows for efficient torque transmission and enables the gear arrangement to achieve different gear ratios based on the relative sizes and positions of the gears.

- Compact Size:

One of the key advantages of planetary gears is their compact size. The internal gear meshing and the arrangement of multiple gear sets within a single gear system contribute to their space-saving design. This makes planetary gears suitable for applications where size and weight restrictions are important considerations.

- Wide Range of Applications:

Planetary gears find applications in various industries and mechanical systems. They are commonly used in automotive transmissions, industrial machinery, robotics, aerospace systems, and more. Their ability to achieve different gear ratios, transmit torque efficiently, and operate in compact spaces makes them versatile solutions in diverse engineering applications.

In summary, planetary gears differ from other types of gear arrangements due to their internal gear meshing, multiple gear sets, central sun gear, orbiting planet gears, compact size, and wide range of applications. These characteristics make planetary gears suitable for achieving various gear ratios, transmitting torque efficiently, and meeting the space requirements of different mechanical systems.

editor by CX 2023-11-02