Product Description

CHINAMFG 33, 0571 2123

Rexroth Piston Motors Parts A2fm90, A2fm125, A2fm107 A6VM200HD1E/63W-VAB1000B-S

A6VM200HA2R2

A6VM200HA2R2-63W-VAB017HA

A6VM200HA2R2-63W-VAB571HA

A6VM200HA2T

A6VM200HA2T-60W-PAB571A

A6VM200HA2T-63W-VAB571A

A6VM200HD1

A6VM200HD1-60W-PAB571B

A6VM200HD1D

A6VM200HD1D-60W-PAB571B

A6VM200HD1D-60W-PAB571B-S

A6VM200HD1D-63W-VAB571B

A6VM200HD1E-63W-VAB571B

A6VM200HD2

A6VM200HD2-60W-PAB571B

A6VM200HD2D

A6VM200HD2D-63W-VAB571B

A6VM200HD2D-63W-VAB571FB

A6VM200HZ1

A6VM200HZ1-63W-VAB017B

AA6VM200EP2DX

AA6VM200EP2DX-63W-VSD51XDB-SK

AA6VM200EP2DX-63W-VSD51XFHB-SK

AA6VM200EP2DX-63W-VSD51XFHB-SK

AA6VM200HA2

AA6VM200HA2-63W-VSD520A-E

AA6VM200HD1

AA6VM200HD1-63W-VSD527B

A6VM215EP600P000A

A6VM215EP600P000A-71MWV0S4A21GV-SR9

A6VLM250HD2

A6VLM250HD2-63W2-VZB571B

A6VM250DA

A6VM250DA-61W-PZB017B

A6VM250DA-61W-VZB571B

A6VM250DA-61W-VZB571B

A6VM250EP2

A6VM250EP2-63W1-VZB571B-SO99

A6VM250EP2-63W2-VZB571B

A6VM250EP2-63W2-VZB571B

A6VM250EP2D

A6VM250EP2D-61W-PZB571B

A6VM250EP2D-61W-VZB571B

A6VM250EP2D-63W1-VZB571B

A6VM250EP2G

A6VM250EP2G-63W1-PZB571B

A6VM250EZ2

A6VM250EZ2-63W2-VZB571B

A6VM250EZ2D

A6VM250EZ2D-63W2-VZB571B

A6VM250HA1

A6VM250HA1-61W-VZB150A-SO16

A6VM250HA1-63W1-VZB571A-SO10

A6VM250HA1T

A6VM250HA1T-63W1-VZB571

A6VM250HA1T-63W2-PZB571A

A6VM250HA2

A6VM250HA2-63W1-VZB571A

A6VM250HA2-63W2-VZB571A-SO175

A6VM250HA2T

A6VM250HA2T-63W1-VZB571A

A6VM250HD1

A6VM250HD1-61W-PZB571B

A6VM250HD1-63W1-PPB571B

A6VM250HD1-63W1-VPB017FB

A6VM250HD1D

A6VM250HD1D-63W1-PZB571B

A6VM250HD1D-63W1-V 017B

A6VM250HD1D-63W1-V 017B

A6VM250HD1D-63W2-VZB571B-SO146

A6VM250HD2

A6VM250HD2-61W-PZB571B

A6VM250HD2-61W-PZB150B-SO8

A6VM250HD2-63W-PZB571B

A6VM250HD2-63W2-VZB571B

A6VM250HD2D

A6VM250HD2D-63W2-VZB571B

A6VM250HD2G

A6VM250HD2G-63W1-VZB571B

A6VM250HD2G-63W2-VZB571B

A6VM250HZ

A6VM250HZ-63W1-VZB571B

A6VM250HZ-63W2-VZB571B

A6VM250HZ-63W2-VZB571B

AA6VM250HA1T

AA6VM250HA1T-61W-PSD520A

AA6VM250HA2T

AA6VM250HA2T-63W1-PSD527A

AA6VM250HA2T-63W1-VSD527 AE

AA6VM250HD2

AA6VM250HD2-61W-PSD657B-SO29

AA6VM250HD2-63W2-PSD527B

A6VM355EP2D

A6VM355EP2D-63W2-VZH157B-SO147

A6VM355FR1

A6VM355FR1-61L-VPH571B-SO63

A6VM355HA1

A6VM355HA1-63W1-PZH571A

A6VM355HA1T

A6VM355HA1T-63W2-VZH571A

A6VM355HA2

A6VM355HA2-63W1-VZH017 A

A6VM355HD2

A6VM355HD2-61W-PZH571B

A6VM355HZ

A6VM355HZ-63W2-VZH571FB

AA6VM355HD1D

AA6VM355HD1D-63W1-VH017B-SO165

A6VM500EP2D 63W2

A6VM500EP2D 63W2-VZH571 B

A6VM500HA1

A6VM500HA1-63W1-VZH571A-SO158

A6VM500HA1T

A6VM500HA1T-63W2-VZH571A-SO158

A6VM500HD1

A6VM500HD1-63W1-PPH571VB

A6VM500HD1-63W1-PZH571B

A10VO28DR/31R-PSC12K01 Germany CHINAMFG orginal Hydraulic pump

A11vlo75 A11vlo95 A11vlo145 A11vlo190 A11vlo260

Rexroth A10VO28 Axial Variable Piston Pump A10VO28DR/31R-PSC12K01 A10VO28

Rexroth plunger pump is widely used in high pressure, large flow, high power system and flow need adjustment occasions, such as planing machine, broaching machine, hydraulic press, engineering machinery such as widely used.A6VM200HD1E–63W–VAB571B

1. Product: Excavator hydraulic parts

2. Standard: Original and OEM

3. Certification: ISO9001

|

Product Name |

Excavator hydraulic parts |

|

Model |

Excavator hydraulic parts |

|

Parts number |

90R55 90R75 90R100 90R130 90R250 |

|

Condition: |

100% new |

|

Warranty |

3months |

|

Availability: |

stock |

|

MOQ(Minimum Order Quantity:) |

1PCS |

|

Seaport |

ZheJiang or HangZhou or HangZhou |

|

Delivery Methods: |

Express: DHL Fedex EMS UPS or By Air/ Sea |

|

Payment Methods: |

Trade assuranse,Bank transfer, Western Union, Money Gram, Credit Card,Paypal |

Rexroth Piston Motors Parts A2fm90, A2fm125, A2fm107

A10VO28DR/31R-PSC12K01

We could supply the CHINAMFG hydraulic pump and motor, also the inner spare parts as below model:

| Other Brand Pump Parts | Model |

| Linde | BPR105/140/186/260;BPV35/50/70/100/200;B2PV35/50/75/105;H3.0/H4.5 travel |

| Linde | HPR75/90/100/130/160;BMV50/55/75/105;BMF35/75/105/140/186/260;MPF55, MPR63 |

| Hitachi | HPV091/102/105/116/130/135/145 |

| Kawasaki | K3V45/63/112/140/180/280; K5V80/140/200 |

| Kawasaki | K3SP36; K3SP30 ; KVC925/930/932; DNB08; NVK45DT; SBS120/140 |

| Komatsu | PC50/60/100/120/150/200/220/300/400(-1/2/3/4/5/6/7)/650;PC45R-8swing motor |

| Rexroth | A10V(S)O10/16/18/28/45/63/71/85/100/140 (H & E first products) |

| Rexroth | A2F10/12/23/28/45/55/63/80/107/125/160/200/225/250/355/500/915/1000; (A2VK…) |

| Rexroth | A2FO10/12/16/23/28/32/45/56/63/80/90/107/125/160/180/250/355/500 |

| Rexroth | A2FE28/32/45/56/63/80/90/107/125/160/180/250/355 |

| Rexroth | A4V(SO)40/45/50/56/71/90/125/180/250/355/500 |

| Rexroth | A4VG25/28/40/45/50/56/71/90/125/140/180/250 |

| Rexroth | A6V(M)28/55/80/107/140/160/200/250/355/500 |

| Rexroth | A7V(O)28/55/80/107/140/160/200/250/355/500/1000 |

| Rexroth | A8V(O)28/55/80/107/140/160/200/250/355/500 |

| Rexroth | A10VGO28/45/63 |

| Rexroth | A11V(L)O50/60/75/95/130/145/160/190/250/260 |

Rexroth Piston Motors Parts A2fm90, A2fm125, A2fm107

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Motor |

|---|---|

| Application: | Pile Driver |

| Certification: | ISO9001: 2000 |

| Condition: | New |

| Transport Package: | Wood |

| Specification: | A10VE45HZ6/52W1-VRF60N000 |

| Customization: |

Available

| Customized Request |

|---|

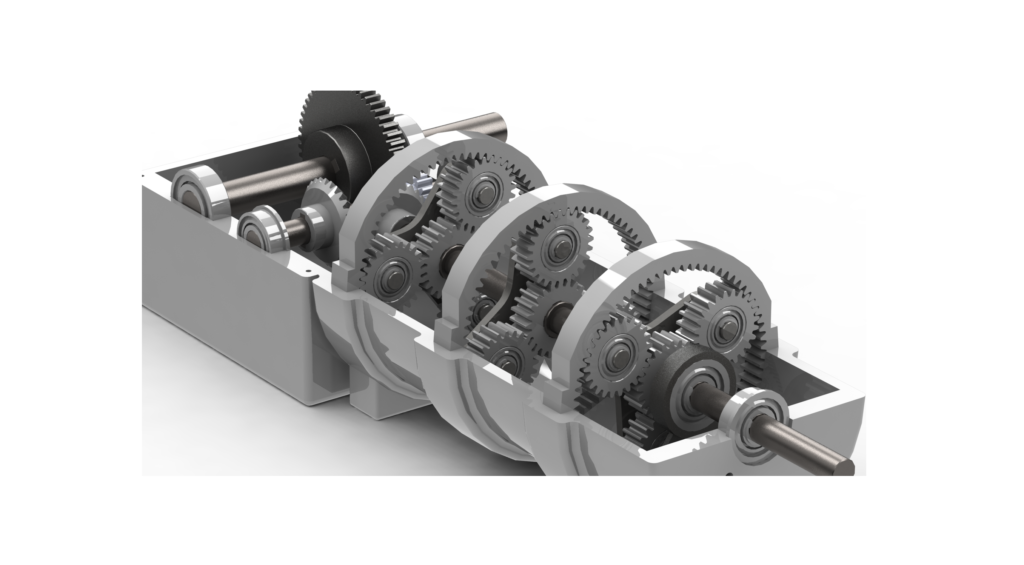

Can planetary gears be used in high-torque applications?

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

Can you explain the process of gear shifting in planetary gear systems?

Gear shifting in planetary gear systems involves changing the gear ratio by engaging or disengaging specific components of the gear set. Let’s explore the process of gear shifting in more detail:

- Clutching and Braking:

The gear shifting process in planetary gear systems primarily relies on clutching and braking mechanisms. These mechanisms selectively connect or disconnect various gears within the system to achieve the desired gear ratio. Here are the key steps involved:

- Clutch Engagement:

To shift to a higher gear ratio, the clutch associated with the gear component that needs to be engaged is activated. The clutch connects the rotating member, such as the sun gear, planet carrier, or ring gear, to the stationary member, allowing torque transmission. This engagement results in a change in the gear ratio, leading to higher speed or torque output depending on the specific gear set configuration.

- Brake Application:

On the other hand, to shift to a lower gear ratio, a brake associated with the gear component that needs to be disengaged is applied. The brake immobilizes or slows down the rotation of the selected gear element, preventing it from transmitting torque. By selectively braking certain components, the gear ratio is altered, resulting in a lower speed or higher torque output.

- Sequential Shifting:

In some planetary gear systems, gear shifting is performed sequentially. This means that one gear component is engaged or disengaged at a time, gradually transitioning from one gear ratio to another. Sequential shifting allows for smooth and controlled gear changes, minimizing the stress on the transmission components and ensuring seamless power transmission.

- Electronic Control:

In modern applications, gear shifting in planetary gear systems is often electronically controlled. Electronic control systems utilize sensors, actuators, and a control unit to monitor various parameters such as vehicle speed, engine load, and driver input. Based on these inputs, the control unit determines the optimal gear shift points and actuates the clutches and brakes accordingly. Electronic control enhances the efficiency, precision, and automation of the gear shifting process.

In summary, gear shifting in planetary gear systems involves the engagement and disengagement of clutches and brakes to alter the gear ratio. By selectively connecting or disconnecting specific gear components, the speed and torque output can be adjusted. Sequential shifting and electronic control systems further enhance the gear shifting process, providing smooth and efficient operation in various applications, including automotive transmissions and industrial machinery.

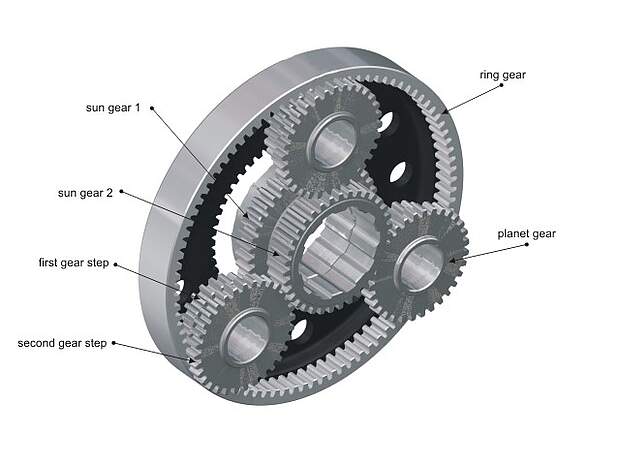

What is a planetary gear and how does it work in mechanical systems?

A planetary gear, also known as an epicyclic gear, is a type of gear system used in mechanical systems to achieve various gear ratios and torque transmission. Let’s explore what a planetary gear is and how it works:

- Definition:

A planetary gear consists of three main components: a sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source, such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Operation:

When the sun gear rotates, it drives the planet gears, causing them to rotate on their own axes while also orbiting around the sun gear. The planet gears are mounted on the carrier, which can rotate independently or be held stationary. As the planet gears rotate and orbit, they engage with the ring gear, which remains fixed or acts as the output. This interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and torque transmission.

- Gear Ratios:

A key advantage of planetary gears is their ability to achieve multiple gear ratios within a compact design. By varying the number of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained. The gear ratio is determined by the ratio of the number of teeth between the sun gear and the ring gear, as well as the speed and direction of rotation of the sun gear.

- Applications:

Planetary gears are widely used in various mechanical systems and applications where precise control of speed, torque, and direction is required. They are commonly found in automotive transmissions, robotics, aerospace systems, industrial machinery, and more. Their compact size, high gear ratios, and torque-carrying capacity make them versatile and efficient in transmitting power.

In summary, a planetary gear is a gear system consisting of a sun gear, planet gears, and a ring gear. It operates by the rotation and orbiting of the planet gears around the sun gear, allowing for different gear ratios and torque transmission. Planetary gears find applications in a wide range of mechanical systems where precise control and efficient power transmission are necessary.

editor by CX 2024-04-09