Product Description

| 810-35199-6651 | Middle bridge basin Angle tooth (37/12) |

| Q50 0571 2 | 6.3 * 32 – ST – A4C cotter pin |

| 712W35125-0571 | Differential adjustment nut |

| 810W93420-0183 | Tapered roller bearing 32571 |

| MQ6571163416 | Differential housing screw |

| 812-35105-0194 | Differential housing |

| 810W9571-5718 | Differential planetary wheel gasket |

| 710W55711- | |

| Q43745 | Retainer ring |

| 810-35199-6598 | Rear axle basin Angle teeth (12/37) |

| 810-35301-6116 | Rear axle main housing reduction assembly |

| WG7117329065 | Rear axle input flange |

| WG7117329018/329001 | Rear axle input oil seal |

| 810W35601-0040 | Bearing housing (rear axle) |

| 812-35105-0061 | Rear axle wheel difference shell |

| WG91571014 | bearing |

| WG91571571 | bearing |

| WG9981032222 | Bearing |

| WG9981032313 | Bearing |

| HR9-ZXJXLB | Steering knuckle repair kit |

| WG9100443050 | Front brake pad |

| 420HP Engine(D12.42) | ||

| VG157171050 | Rear oil seal | 1 |

| VG1246571005 | Front oil seal | 1 |

| VG260571208 | Flywheel gear ring | 1 |

| AZ1242571561 | Flywheel assembly | 1 |

| VG1246030011/12 | Connecting rod tile | 1 |

| VG1246571034/35 | Main bearing | 1 |

| AZ1246030007 | Connecting rod assembly | 6 |

| VG1246030013 | Connecting rod bolt | 12 |

| VG1246030015 | Piston assembly | 6 |

| VG1540030005 | Piston ring | 1 |

| VG1246030002 | Piston pin | 6 |

| VG1246571571 | Cylinder liner | 6 |

| D12.42-XLB | Engine repair kit | 1 |

| VG1246040571 | Cylinder pad | 6 |

| VG1246050571/22 | Intake and exhaust valve | 1 |

| VG1246 0571 1 | Valve push rod | 12 |

| VG1246 0571 1 | Valve tappet | 12 |

| VG1246060091 | Belt | 1 |

| VG1246060005 | Automatic tensioning wheel | 1 |

| VG1246060094 | Pump assembly | 1 |

| VG1246060088 | Belt | 1 |

| VG1246060051 | Fan leaves | 1 |

| VG1246070012 | Oil cooler core | 1 |

| VG1246080002 | High-pressure pipeline | 1 |

| VG1246090017 | generator | 1 |

| VG1246090002 | starter | 1 |

| VG124611571 | Turbocharger | 1 |

| VG1246130008 | Air compressor | 1 |

| VG12465716 | Fuel injector assembly | 6 |

| WG9731471571 | Steering vane pump | 1 |

| VG1246070031 | Oil filter | 2 |

| VG1540080110 | Diesel filter | 1 |

| VG | Diesel filter | 1 |

| WG9725195712/103 | air filter | 1 |

| After-sales Service: | Online Support |

|---|---|

| Warranty: | 6months |

| Type: | Chassis |

| Certification: | ISO14001 |

| Driving System Parts: | Suspension |

| Electrical System Parts: | Lighting |

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) | |

|---|

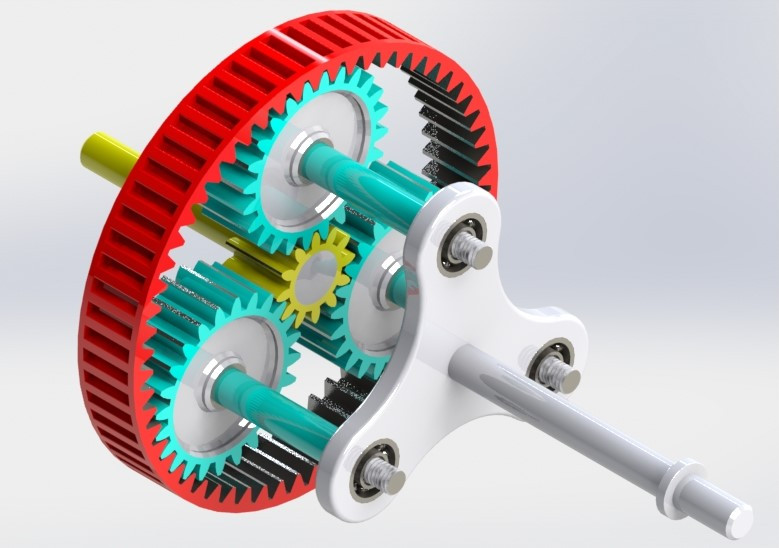

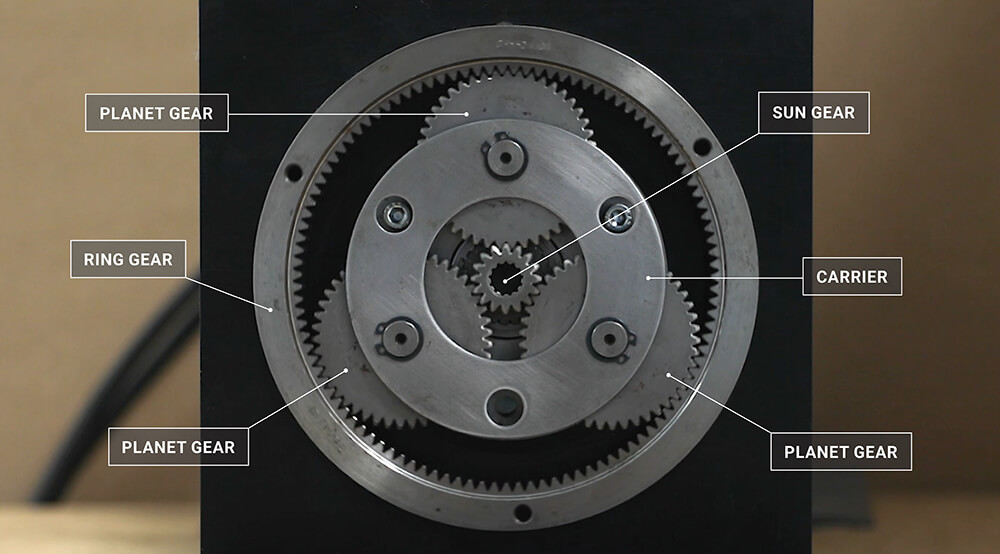

How do planetary gears handle changes in speed and torque distribution?

Planetary gears are capable of effectively handling changes in speed and torque distribution due to their unique design and configuration. Let’s explore how planetary gears handle these changes:

- Speed Changes:

Planetary gears can handle speed changes by utilizing the different gear ratios they offer. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. When the input speed is applied to the sun gear, it gets transmitted to the planet gears, resulting in a specific output speed. By changing the gear ratio, the output speed can be adjusted accordingly. This ability to vary the gear ratio allows planetary gears to adapt to different speed requirements in mechanical systems.

- Torque Distribution:

Planetary gears excel in distributing torque across multiple gear teeth, ensuring efficient torque transmission and load sharing. The planet gears are meshed with both the sun gear and the ring gear, enabling torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. The load is shared among the planet gears, preventing excessive wear and minimizing the risk of gear failure.

- Torque Amplification:

Planetary gears can also handle torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The arrangement of multiple gear sets in a compact design enables torque amplification, making planetary gears suitable for applications that require high torque output while maintaining a smaller physical size.

- Load Balancing:

Another aspect of torque distribution in planetary gears is load balancing. The planet gears distribute the load across multiple gear teeth, reducing the concentration of forces on individual teeth. This load balancing capability results in improved gear system durability and longevity. It also helps in minimizing vibration, noise, and wear, ensuring smoother and more reliable operation.

- Flexible Configuration:

Planetary gears offer flexibility in their configuration, allowing for the accommodation of changes in speed and torque distribution. The number of planet gears, the size of the gears, and their arrangement can be adjusted to meet specific application requirements. This flexibility enables planetary gears to handle a wide range of speed and torque variations, making them adaptable to different mechanical setups.

In summary, planetary gears handle changes in speed and torque distribution through their ability to adjust gear ratios, distribute torque across multiple gear teeth, amplify torque, balance loads, and accommodate flexible configurations. These characteristics make planetary gears suitable for applications that require precise control over speed and torque, efficient power transmission, and reliable performance.

How do planetary gears handle variations in direction and torque transmission?

Planetary gears are versatile mechanisms that can effectively handle variations in direction and torque transmission. Let’s explore how they achieve this:

- Direction Reversal:

Planetary gears are capable of transmitting torque in both forward and reverse directions. By changing the input and output connections, the direction of rotation can be reversed without the need for additional components or complex mechanisms. This makes planetary gears well-suited for applications where frequent changes in direction are required, such as automotive transmissions.

- Torque Amplification and Reduction:

One of the notable characteristics of planetary gears is their ability to amplify or reduce torque depending on the arrangement of gear components. Let’s consider a basic arrangement with a sun gear, planet gears, and a ring gear:

- Torque Amplification:

When the sun gear is the input and the ring gear is the output, the planet gears rotate on their own axes while also revolving around the sun gear. This arrangement allows for torque amplification, meaning the output torque can be higher than the input torque. This is particularly useful in applications where higher torque is required, such as heavy machinery or power transmission systems.

- Torque Reduction:

Conversely, by fixing the ring gear and using the sun gear as the output, the planet gears rotate on their own axes while also revolving around the fixed ring gear. In this configuration, the output torque is lower than the input torque, enabling torque reduction. This can be advantageous in applications where torque needs to be reduced, such as speed reduction systems or precision machinery.

- Combination of Gear Stages:

Planetary gears can be combined into multiple stages, with each stage having its own set of sun gears, planet gears, and ring gears. This arrangement allows for further variations in torque transmission. By connecting the output of one stage to the input of another, the torque can be further amplified or reduced, providing flexibility in power transmission systems.

- Custom Gear Ratios:

By selecting the appropriate sizes and numbers of teeth for the sun gears, planet gears, and ring gears, custom gear ratios can be achieved in planetary gear systems. This allows for precise control over torque transmission and enables the adaptation of the gear arrangement to specific application requirements.

In summary, planetary gears handle variations in direction and torque transmission through their ability to reverse direction without additional components, torque amplification or reduction based on gear arrangement, combination of multiple gear stages, and the ability to achieve custom gear ratios. These features make planetary gears a versatile choice for a wide range of applications requiring efficient and flexible power transmission.

How do planetary gears contribute to power transmission and gear reduction?

Planetary gears play a significant role in power transmission and gear reduction. Let’s explore how planetary gears contribute to these aspects:

- Torque Amplification:

One of the key contributions of planetary gears is torque amplification. The arrangement of multiple gear sets in a compact design allows for torque multiplication. When the input power is applied to the sun gear, it drives the rotation of the planet gears. The planet gears, in turn, mesh with the ring gear, creating a mechanical advantage that amplifies the torque output. This torque amplification is beneficial in applications where high torque is required while maintaining a smaller form factor.

- Gear Ratio Variation:

Another contribution of planetary gears is their ability to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. This flexibility in gear ratios allows machinery to adapt to varying speed and torque requirements, enabling precise control and efficient power transmission.

- Gear Reduction:

Planetary gears are commonly used for gear reduction applications. Gear reduction refers to the process of reducing the rotational speed and increasing the torque output of a power source. In a planetary gear system, gear reduction is achieved by fixing the ring gear and allowing the sun gear to rotate as the input. The rotation of the sun gear drives the planet gears, which in turn rotate the output carrier or arm. The output speed is slower than the input speed, resulting in gear reduction. This gear reduction capability is valuable in various applications, such as automotive transmissions and power transmission systems.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. The load is shared among the planet gears, allowing for higher torque capacity and reduced wear on individual gear teeth. This efficient power transmission ensures that a significant portion of the input power is effectively transmitted to the output, making planetary gears suitable for applications where energy conservation and optimization are crucial.

In summary, planetary gears contribute to power transmission and gear reduction through torque amplification, gear ratio variation, gear reduction mechanism, and efficient power transmission. The ability to amplify torque, achieve different gear ratios, and transmit power efficiently makes planetary gears widely used in various industries and mechanical systems.

editor by CX 2023-09-08