Product Description

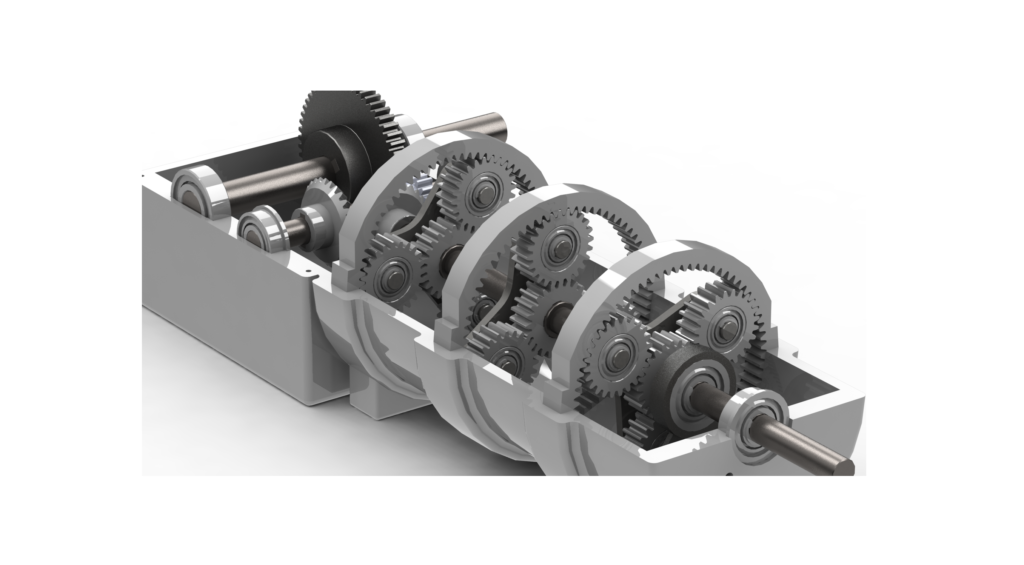

28mm Planetary Motor Cheap gearbox with plastic gears

Drawing:

| Type | Ratio | 1: 3.7 | 1: 5 | 1: 16 | 1: 19 | 1: 27 | 1: 51 | 1: 79 | 1: 100 | 1: 139 | 1: 190 | 1: 253 | 1: 305 | 1: 352 | 1: 408 | 1: 516 | 1: 596 | 1: 721 | 1: 1012 | |

| D283 | Rated torque | kg. cm | 0.36 | 0.49 | 1.4 | 1.6 | 2.3 | 4 | 6 | 7.5 | 11 | 13 | 18 | 21 | 25 | 29 | 30 | 30 | 30 | 30 |

| Rated speed | rpm | 1830 | 1360 | 425 | 357 | 251 | 133 | 86 | 68 | 48 | 35 | 26 | 22 | 19 | 16 | 13 | 11.5 | 10 | 6.5 | |

| Gearbox | Instantaneous torque | Kg. cm | 10 | 20 | 30 | 40 | ||||||||||||||

| Allowable torque | Kg. cm | 5 | 10 | 20 | 30 | |||||||||||||||

| Length | mm | 28 | 35 | 42 | 49 | |||||||||||||||

| Backlash | O | 0.7 | 0.8 | 1 | 1 | |||||||||||||||

| Weight | g | 120 | 150 | 180 | 210 | |||||||||||||||

About Us:

I.CH was founded in 2006, located in HangZhou. We specialized in researching, developing, and servicing electric motors, gearbox, and high precision gears with the small module. After years of development, we have an independent product design and R&D team, service team, and a professional quality control team. To realize our service concept better, provide high-quality products and excellent service, we have been committed to the core ability and training. We have a holding factory in HangZhou, which produces high precision small mold gears, gear shaft, gearbox, and planetary gearbox assembling.

Our Product:

DC Gear Motor | DC Planetary Gear Motor

Planetary Gearbox | Spur Gearbox

Spur Gear | Helical Gear

Our Certificate:

As we all know, the success of the company is based on the quality of the motor. So, to get the acknowledgment in the market, we get ROHS, CE, ISO900 certificates.

Work-flow:

Service:

ODM & OEM

Gearbox design and development

Package&Ship:

Carton, pallet, or what you want

The delivery time is about 30-45 days.

Customer’s Visiting:

FAQ:

1. Can you custom gearbox?

YES. The specifications can be designed according to the customer’s requirements.

2. DO you provide the sample?

YES.

3. Do you provide technical support?

YES.we have an independent product design and R&D team, service team and professional quality control team.

4. Do you have a factory?

Yes, we are a professional manufacturer.

5. Can I come to your company to visit?

YES

Related Products:

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Home, Household Appliances |

|---|---|

| Type: | Electric Chair Massager |

| Packing: | Carton or Pallet |

| Customization: |

Available

| Customized Request |

|---|

What is the significance of the gear ratio in planetary gear arrangements?

The gear ratio plays a significant role in planetary gear arrangements, offering several key advantages and applications. Let’s explore the significance of the gear ratio:

- Speed Control:

The gear ratio in planetary gear arrangements allows for precise speed control. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. The gear ratio determines the relationship between the input speed and the output speed. By changing the gear ratio, the speed of the output shaft can be increased or decreased relative to the input speed. This speed control capability is crucial in various applications, such as automotive transmissions, industrial machinery, and robotics, where specific speed requirements are necessary for optimal performance.

- Torque Amplification:

The gear ratio also enables torque amplification in planetary gear arrangements. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The gear ratio determines the extent of torque amplification. This torque amplification feature is beneficial in applications that require higher torque output while maintaining a smaller physical size. It allows for increased torque transmission without the need for larger and heavier gear systems.

- Multiple Speeds:

Another significance of the gear ratio is the ability to achieve multiple speeds within a single gear system. Planetary gears offer the advantage of having multiple gear sets within a compact arrangement. By combining different gear ratios using various combinations of sun gears, planet gears, and ring gears, it is possible to obtain multiple output speeds. This versatility is useful in applications that require variable speed control or the ability to switch between different operational modes.

- Power Distribution:

The gear ratio also influences power distribution in planetary gear arrangements. As torque is transmitted through the gears, the gear ratio determines how the power is distributed among the different components. By adjusting the gear ratio, it is possible to distribute power more evenly or concentrate it on specific gear elements. This power distribution capability allows for optimized performance and load-sharing in the gear system.

- Efficiency and Mechanical Advantage:

The gear ratio affects the efficiency and mechanical advantage of planetary gear arrangements. The gear ratio determines the trade-off between speed and torque. Increasing the gear ratio results in higher torque output but lower speed, while decreasing the gear ratio yields higher speed but lower torque. By selecting the appropriate gear ratio, it is possible to achieve the desired balance between speed and torque while maximizing the overall efficiency of the system.

In summary, the gear ratio in planetary gear arrangements is significant for speed control, torque amplification, achieving multiple speeds, power distribution, efficiency, and mechanical advantage. Understanding and selecting the appropriate gear ratio is crucial for optimizing performance and meeting the specific requirements of different mechanical setups.

How do planetary gears handle variations in tooth engagement during operation?

Planetary gears are designed to handle variations in tooth engagement during operation, ensuring smooth and reliable performance. Let’s explore how planetary gears address these variations:

- Tolerance for Misalignment:

Planetary gears are designed with a certain degree of tolerance for misalignment. This means that slight variations in tooth engagement due to manufacturing tolerances, assembly, or operating conditions are accommodated without causing significant impact on the gear system. The gear teeth are carefully designed with appropriate profiles, clearances, and backlash to allow for some degree of misalignment while maintaining proper functioning.

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load across multiple gear teeth. Each planet gear shares the load with the adjacent gears, reducing the stress on individual teeth and promoting even tooth engagement. This load distribution capability helps minimize localized wear, noise, and vibration, resulting in smoother and more efficient operation.

- Flexible Mounting and Support:

Planetary gears are often mounted on flexible support structures, such as bearings or flexible couplings. These components help absorb and compensate for small variations in tooth engagement during operation. The flexible mounting and support systems provide some degree of flexibility and compliance, allowing the gears to self-adjust and maintain proper tooth contact under varying operating conditions.

- Lubrication and Cooling:

Proper lubrication and cooling play a crucial role in handling variations in tooth engagement. Lubricants reduce friction and wear between gear teeth, ensuring smooth operation and minimizing the impact of tooth engagement variations. Additionally, effective cooling mechanisms help dissipate heat generated during operation, preventing excessive temperature rise that could affect the gear meshing performance.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques. This robust construction enhances the gear system’s ability to withstand variations in tooth engagement. By ensuring high-quality gear components, proper heat treatment, and stringent quality control, planetary gears are built to handle the dynamic loads and variations encountered during operation.

In summary, planetary gears handle variations in tooth engagement through their tolerance for misalignment, load distribution among multiple planet gears, flexible mounting and support, effective lubrication and cooling, and robust construction. These design considerations and features enable planetary gears to maintain proper tooth contact, minimize wear and noise, and ensure reliable performance in various applications, including automotive transmissions, industrial machinery, and power transmission systems.

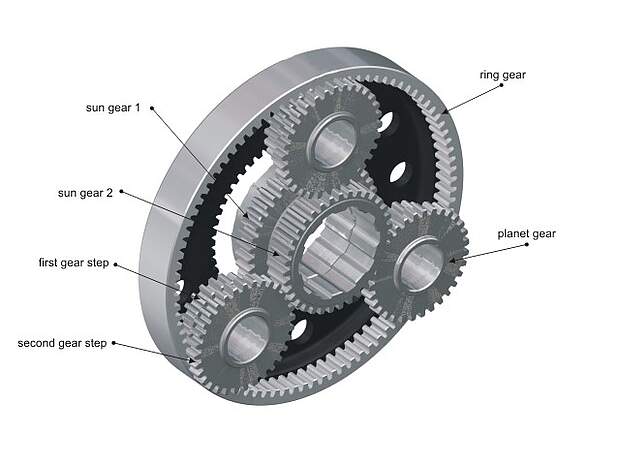

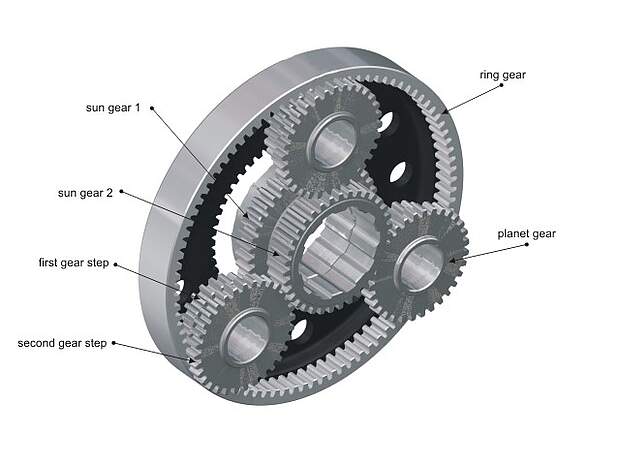

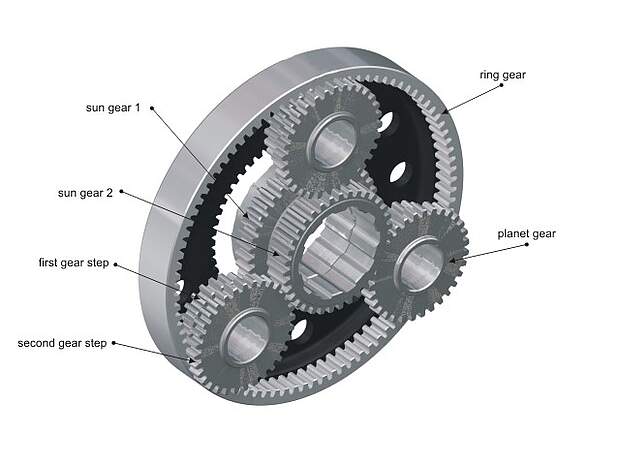

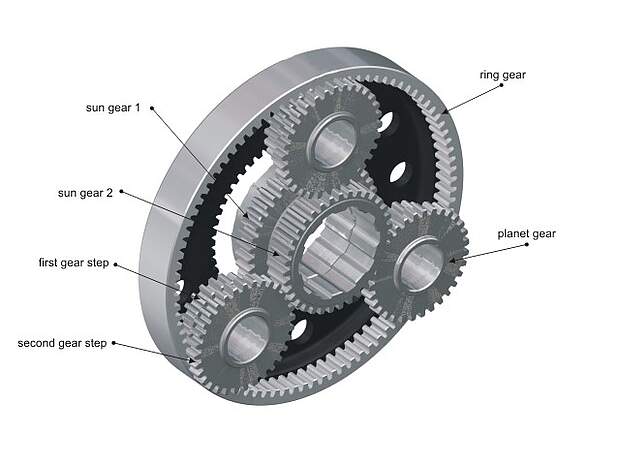

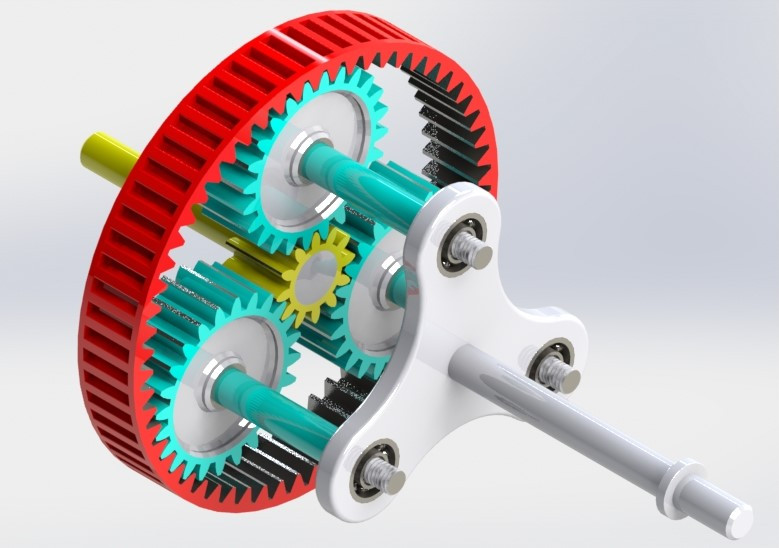

What is a planetary gear and how does it work in mechanical systems?

A planetary gear, also known as an epicyclic gear, is a type of gear system used in mechanical systems to achieve various gear ratios and torque transmission. Let’s explore what a planetary gear is and how it works:

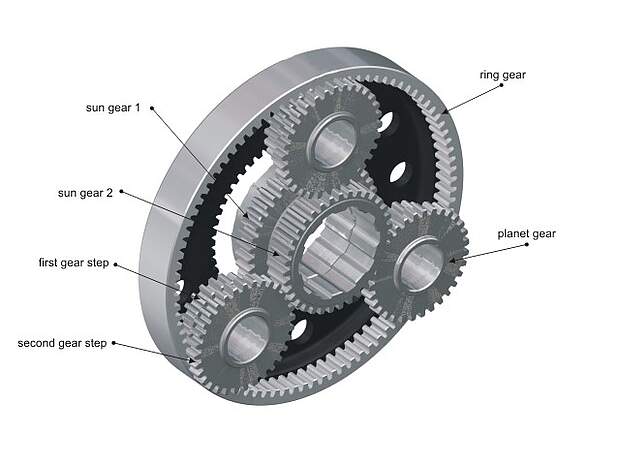

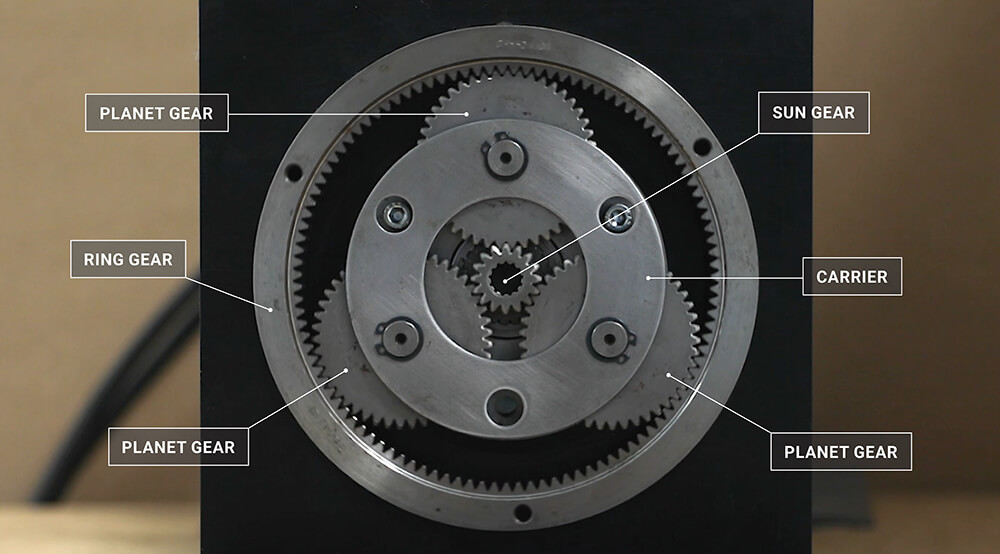

- Definition:

A planetary gear consists of three main components: a sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source, such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Operation:

When the sun gear rotates, it drives the planet gears, causing them to rotate on their own axes while also orbiting around the sun gear. The planet gears are mounted on the carrier, which can rotate independently or be held stationary. As the planet gears rotate and orbit, they engage with the ring gear, which remains fixed or acts as the output. This interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and torque transmission.

- Gear Ratios:

A key advantage of planetary gears is their ability to achieve multiple gear ratios within a compact design. By varying the number of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained. The gear ratio is determined by the ratio of the number of teeth between the sun gear and the ring gear, as well as the speed and direction of rotation of the sun gear.

- Applications:

Planetary gears are widely used in various mechanical systems and applications where precise control of speed, torque, and direction is required. They are commonly found in automotive transmissions, robotics, aerospace systems, industrial machinery, and more. Their compact size, high gear ratios, and torque-carrying capacity make them versatile and efficient in transmitting power.

In summary, a planetary gear is a gear system consisting of a sun gear, planet gears, and a ring gear. It operates by the rotation and orbiting of the planet gears around the sun gear, allowing for different gear ratios and torque transmission. Planetary gears find applications in a wide range of mechanical systems where precise control and efficient power transmission are necessary.

editor by CX 2023-09-14

China manufacturer Worm Gear and Worm Gearbox/Agricultural Machinery/Hardware/Planetary Gears/Transmission/Starter/CNC Machining/Drive Gears Pto and Transmission Shaft 7 with Great quality

Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the significance of the gear ratio in planetary gear arrangements?

The gear ratio plays a significant role in planetary gear arrangements, offering several key advantages and applications. Let’s explore the significance of the gear ratio:

- Speed Control:

The gear ratio in planetary gear arrangements allows for precise speed control. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. The gear ratio determines the relationship between the input speed and the output speed. By changing the gear ratio, the speed of the output shaft can be increased or decreased relative to the input speed. This speed control capability is crucial in various applications, such as automotive transmissions, industrial machinery, and robotics, where specific speed requirements are necessary for optimal performance.

- Torque Amplification:

The gear ratio also enables torque amplification in planetary gear arrangements. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The gear ratio determines the extent of torque amplification. This torque amplification feature is beneficial in applications that require higher torque output while maintaining a smaller physical size. It allows for increased torque transmission without the need for larger and heavier gear systems.

- Multiple Speeds:

Another significance of the gear ratio is the ability to achieve multiple speeds within a single gear system. Planetary gears offer the advantage of having multiple gear sets within a compact arrangement. By combining different gear ratios using various combinations of sun gears, planet gears, and ring gears, it is possible to obtain multiple output speeds. This versatility is useful in applications that require variable speed control or the ability to switch between different operational modes.

- Power Distribution:

The gear ratio also influences power distribution in planetary gear arrangements. As torque is transmitted through the gears, the gear ratio determines how the power is distributed among the different components. By adjusting the gear ratio, it is possible to distribute power more evenly or concentrate it on specific gear elements. This power distribution capability allows for optimized performance and load-sharing in the gear system.

- Efficiency and Mechanical Advantage:

The gear ratio affects the efficiency and mechanical advantage of planetary gear arrangements. The gear ratio determines the trade-off between speed and torque. Increasing the gear ratio results in higher torque output but lower speed, while decreasing the gear ratio yields higher speed but lower torque. By selecting the appropriate gear ratio, it is possible to achieve the desired balance between speed and torque while maximizing the overall efficiency of the system.

In summary, the gear ratio in planetary gear arrangements is significant for speed control, torque amplification, achieving multiple speeds, power distribution, efficiency, and mechanical advantage. Understanding and selecting the appropriate gear ratio is crucial for optimizing performance and meeting the specific requirements of different mechanical setups.

Can you explain the process of gear shifting in planetary gear systems?

Gear shifting in planetary gear systems involves changing the gear ratio by engaging or disengaging specific components of the gear set. Let’s explore the process of gear shifting in more detail:

- Clutching and Braking:

The gear shifting process in planetary gear systems primarily relies on clutching and braking mechanisms. These mechanisms selectively connect or disconnect various gears within the system to achieve the desired gear ratio. Here are the key steps involved:

- Clutch Engagement:

To shift to a higher gear ratio, the clutch associated with the gear component that needs to be engaged is activated. The clutch connects the rotating member, such as the sun gear, planet carrier, or ring gear, to the stationary member, allowing torque transmission. This engagement results in a change in the gear ratio, leading to higher speed or torque output depending on the specific gear set configuration.

- Brake Application:

On the other hand, to shift to a lower gear ratio, a brake associated with the gear component that needs to be disengaged is applied. The brake immobilizes or slows down the rotation of the selected gear element, preventing it from transmitting torque. By selectively braking certain components, the gear ratio is altered, resulting in a lower speed or higher torque output.

- Sequential Shifting:

In some planetary gear systems, gear shifting is performed sequentially. This means that one gear component is engaged or disengaged at a time, gradually transitioning from one gear ratio to another. Sequential shifting allows for smooth and controlled gear changes, minimizing the stress on the transmission components and ensuring seamless power transmission.

- Electronic Control:

In modern applications, gear shifting in planetary gear systems is often electronically controlled. Electronic control systems utilize sensors, actuators, and a control unit to monitor various parameters such as vehicle speed, engine load, and driver input. Based on these inputs, the control unit determines the optimal gear shift points and actuates the clutches and brakes accordingly. Electronic control enhances the efficiency, precision, and automation of the gear shifting process.

In summary, gear shifting in planetary gear systems involves the engagement and disengagement of clutches and brakes to alter the gear ratio. By selectively connecting or disconnecting specific gear components, the speed and torque output can be adjusted. Sequential shifting and electronic control systems further enhance the gear shifting process, providing smooth and efficient operation in various applications, including automotive transmissions and industrial machinery.

How do planetary gears contribute to power transmission and gear reduction?

Planetary gears play a significant role in power transmission and gear reduction. Let’s explore how planetary gears contribute to these aspects:

- Torque Amplification:

One of the key contributions of planetary gears is torque amplification. The arrangement of multiple gear sets in a compact design allows for torque multiplication. When the input power is applied to the sun gear, it drives the rotation of the planet gears. The planet gears, in turn, mesh with the ring gear, creating a mechanical advantage that amplifies the torque output. This torque amplification is beneficial in applications where high torque is required while maintaining a smaller form factor.

- Gear Ratio Variation:

Another contribution of planetary gears is their ability to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. This flexibility in gear ratios allows machinery to adapt to varying speed and torque requirements, enabling precise control and efficient power transmission.

- Gear Reduction:

Planetary gears are commonly used for gear reduction applications. Gear reduction refers to the process of reducing the rotational speed and increasing the torque output of a power source. In a planetary gear system, gear reduction is achieved by fixing the ring gear and allowing the sun gear to rotate as the input. The rotation of the sun gear drives the planet gears, which in turn rotate the output carrier or arm. The output speed is slower than the input speed, resulting in gear reduction. This gear reduction capability is valuable in various applications, such as automotive transmissions and power transmission systems.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. The load is shared among the planet gears, allowing for higher torque capacity and reduced wear on individual gear teeth. This efficient power transmission ensures that a significant portion of the input power is effectively transmitted to the output, making planetary gears suitable for applications where energy conservation and optimization are crucial.

In summary, planetary gears contribute to power transmission and gear reduction through torque amplification, gear ratio variation, gear reduction mechanism, and efficient power transmission. The ability to amplify torque, achieve different gear ratios, and transmit power efficiently makes planetary gears widely used in various industries and mechanical systems.

editor by CX 2023-09-13

China OEM Wholesale CZPTAC16 Axle Planetary Gear for CZPTCZPTTruck Spare Parts with Great quality

Product Description

Wholesale CHINAMFG CHINAMFG AC16 Axle Planetary Gear for CHINAMFG CHINAMFG CHINAMFG CHINAMFG Truck Spare Parts

Packing

|

Packaging Details: |

wooden case or depend on client’s requirement |

|

Delivery Detail: |

5-7 days after receiving payment |

Quick Details

|

Size: |

Standard |

Packing: |

Carton Box |

|

Payment term: |

T/T,L/C |

Place: |

HangZhou,ZheJiang |

HangZhou CHINAMFG Truck Parts Co.,Ltd was established in2002 with a registered capital of 5000,000rmb, our company is located in HangZhou, which is the truck and truck parts production base in China. It mainly deals in Chinese truck and truck parts which include: CHINAMFG Sinotruck- CHINAMFG Series(Which was authorized by Sinotruck), Shacman, Xihu (West Lake) Dis.,Xihu (West Lake) Dis.feng, jac, Camc, Beifang, Benz, etc, We also deals in heavy, light truck series and their parts. The products that our company distribute, mainly supplied to the foreign construction companies and transportation companies who use heavy trucks.

Our Services

1 . High quality with competitive services.

2. Good after sale service

3. Long serving time.

4 . High reputation at home and abroad.

5. Good performance and reliability

FAQ

1. Q:What’s your best price for this product?

A: We will quote you best price according to your quantity, so when you making an inquiry, please let us know the quantity you want.The more quantity the better price.

2. Q:How about the quality of this product?

A: Our products are certified to ISO9001 international quality standards. We compay have very strict Quality Control Systems.

3. Q:Can we custom our own logo or label on this product?

A: Yes, you can. we support logo print & stamping & label print, print will be free if the logo is not very complex.

4. Q:What about the warranty?

A: We are very confident in our products, and we pack them very well to make sure the goods in well protection

| After-sales Service: | Three Months After Loading |

|---|---|

| Warranty: | Three Months After Loading |

| Material: | Steel |

| Transport Package: | Standard Brand Packing & Wooden Case Package & Cus |

| Specification: | Standard |

| Trademark: | SINOTRUCK |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in high-torque applications?

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature:

Monitor the operating temperature of the gear system. Excessive heat can degrade the lubricant’s performance and accelerate wear. Proper cooling mechanisms, such as fans or heat exchangers, may be required in high-temperature environments.

In summary, proper lubrication and maintenance are essential for planetary gears. Choose suitable lubricants, prevent contamination, follow recommended lubrication intervals, inspect for wear, ensure proper alignment, consider torque and load limits, monitor operating temperature, and conduct regular maintenance. By adhering to these considerations, you can prolong the lifespan, enhance performance, and minimize the risk of gear failure in planetary gear systems.

How do planetary gears contribute to power transmission and gear reduction?

Planetary gears play a significant role in power transmission and gear reduction. Let’s explore how planetary gears contribute to these aspects:

- Torque Amplification:

One of the key contributions of planetary gears is torque amplification. The arrangement of multiple gear sets in a compact design allows for torque multiplication. When the input power is applied to the sun gear, it drives the rotation of the planet gears. The planet gears, in turn, mesh with the ring gear, creating a mechanical advantage that amplifies the torque output. This torque amplification is beneficial in applications where high torque is required while maintaining a smaller form factor.

- Gear Ratio Variation:

Another contribution of planetary gears is their ability to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. This flexibility in gear ratios allows machinery to adapt to varying speed and torque requirements, enabling precise control and efficient power transmission.

- Gear Reduction:

Planetary gears are commonly used for gear reduction applications. Gear reduction refers to the process of reducing the rotational speed and increasing the torque output of a power source. In a planetary gear system, gear reduction is achieved by fixing the ring gear and allowing the sun gear to rotate as the input. The rotation of the sun gear drives the planet gears, which in turn rotate the output carrier or arm. The output speed is slower than the input speed, resulting in gear reduction. This gear reduction capability is valuable in various applications, such as automotive transmissions and power transmission systems.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. The load is shared among the planet gears, allowing for higher torque capacity and reduced wear on individual gear teeth. This efficient power transmission ensures that a significant portion of the input power is effectively transmitted to the output, making planetary gears suitable for applications where energy conservation and optimization are crucial.

In summary, planetary gears contribute to power transmission and gear reduction through torque amplification, gear ratio variation, gear reduction mechanism, and efficient power transmission. The ability to amplify torque, achieve different gear ratios, and transmit power efficiently makes planetary gears widely used in various industries and mechanical systems.

editor by CX 2023-09-13

China supplier Custom Cylindrical Spur Gear / POM Delrin Small Gears / Plastic Ratchet Gear / Planetary Gear worm gear motor

Product Description

Cylindrical Spur Gear / POM Delrin Small Gears / Plastic Ratchet Gear / Planetary Gear

Products Type

We can custom shape,size,color material and quantity for plastic gear as your requirment.

Products Specification

1. Various hardness for your choice.

2. Good abrasion, heat and oil resistance.

3. Good anti-aging performance and gas tightness.

4. Ease of bonding to other material.

5. Excellent oxygen and CZPT resistance.

6. Non-flammable,self-extinguish.

| Material | PA,PA6,PA66,PP,PE,LDPE,HDPE,UWHDPE,PTFE,POM,ABS,or Custom Compound (Any custom compound plastic is available) |

| Size | According to samples or drawings |

| Color | Black,white,red,green,transparent or any color according to Pantone colors |

| Finish | High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

| Type | Round,square,rectangular,or any nonstandard shape as request |

| Logo | Debossed,embossed,printed logo or as request |

Our Advantage:

Comprehensive Materials

Stock more than 50+ types of material, CZPT is able to supply all the most common plastic and rubber material in the market. We also provide material modification services for unique using environments.

Considerate Service

Our engineers will 24/7 work with you throughout the course of your project, Together, we will discuss your unique design and help you optimize the parts, and also provide DFM reports if required, all is free.

Reasonable Price

Our quote includes real-time pricing and design analysis. We evaluate your 3D CAD and help identify any features that may pose challenges during the molding process, Ensure that each quote is Well-founded.

Quality control Departments

ISO and SGS certified manufacturer has professional quality control departments. Strictly inspect every process of mold and production, each problem can be traced back. Reduce error correction time and defective rate as low as 1%

Our Factory

Customization Capabilities

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in automotive applications?

Planetary gears are widely used in various automotive applications due to their numerous advantages. Let’s explore how planetary gears can be utilized in the automotive industry:

- Automatic Transmissions:

One of the primary applications of planetary gears in automobiles is in automatic transmissions. Automatic transmissions use a combination of planetary gear sets to achieve different gear ratios, allowing for smooth and efficient shifting between gears. The compact size and high torque capacity of planetary gears make them well-suited for this purpose, providing reliable and efficient power transmission in vehicles.

- Four-Wheel Drive Systems:

Planetary gears are also employed in four-wheel drive systems, where they help distribute power between the front and rear wheels. By utilizing planetary gear arrangements, the torque can be split between the front and rear axles, providing improved traction and stability on various road conditions. This allows vehicles to have enhanced off-road capabilities and better performance in challenging driving situations.

- Hybrid and Electric Vehicles:

Planetary gears play a crucial role in hybrid and electric vehicle powertrains. In these vehicles, planetary gear sets are often used to combine the power from the internal combustion engine and the electric motor. The gear arrangement allows for seamless transitions between different power sources, enabling efficient energy management and optimized performance.

- Start-Stop Systems:

Start-stop systems, which automatically shut off the engine when the vehicle is stationary and restart it when needed, often incorporate planetary gears. These gears help engage and disengage the engine from the drivetrain smoothly, ensuring a quick and seamless transition between the engine’s off and on states. Planetary gears contribute to the overall efficiency and reliability of start-stop systems.

- Power Steering:

Some power steering systems in automobiles utilize planetary gears to provide assistance in steering. These gears help amplify the driver’s input torque, making steering easier and more responsive. The compact size and high torque capacity of planetary gears make them suitable for power steering applications.

In summary, planetary gears find extensive use in automotive applications, including automatic transmissions, four-wheel drive systems, hybrid and electric vehicle powertrains, start-stop systems, and power steering. Their compact size, high torque capacity, and ability to achieve multiple gear ratios make them well-suited for these applications, providing efficient power transmission, improved performance, and enhanced driving experience in vehicles.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature:

Monitor the operating temperature of the gear system. Excessive heat can degrade the lubricant’s performance and accelerate wear. Proper cooling mechanisms, such as fans or heat exchangers, may be required in high-temperature environments.

In summary, proper lubrication and maintenance are essential for planetary gears. Choose suitable lubricants, prevent contamination, follow recommended lubrication intervals, inspect for wear, ensure proper alignment, consider torque and load limits, monitor operating temperature, and conduct regular maintenance. By adhering to these considerations, you can prolong the lifespan, enhance performance, and minimize the risk of gear failure in planetary gear systems.

What industries commonly use planetary gears in their applications?

Planetary gears find applications in a wide range of industries and mechanical systems. Let’s explore some of the industries that commonly utilize planetary gears:

- Automotive Industry:

The automotive industry extensively uses planetary gears in various applications. Planetary gears are commonly found in automatic transmissions, where they enable smooth gear shifting, provide different gear ratios, and transmit torque efficiently. They are also used in differential systems, allowing wheels to rotate at different speeds while maintaining power distribution.

- Robotics and Automation:

Planetary gears play a crucial role in robotics and automation systems. They are employed in robotic joints and actuators to provide precise motion control, compact size, and high torque transmission. Planetary gears enable robotic arms to move accurately and handle heavy loads, making them essential components in industrial robots and robotic manipulators.

- Aerospace and Aviation:

The aerospace and aviation industries utilize planetary gears in various applications. They are used in aircraft landing gear systems, where they provide reliable torque transmission and compact design. Planetary gears are also employed in aircraft engine systems, helicopter rotor systems, and satellite mechanisms due to their efficiency, high torque capacity, and ability to operate in space-restricted environments.

- Power Generation:

Planetary gears are utilized in power generation equipment, including wind turbines and hydroelectric generators. In wind turbines, planetary gears enable the conversion of low-speed rotor rotation to high-speed generator rotation, ensuring efficient power generation. They are also employed in hydroelectric generators to transmit power from turbines to electrical generators, providing gear reduction and torque amplification.

- Industrial Machinery:

Planetary gears are widely used in industrial machinery applications. They are found in heavy-duty machinery such as mining equipment, construction machinery, and material handling systems. Planetary gears provide high torque transmission, compactness, and durability, making them suitable for handling demanding tasks in industrial environments.

- Marine and Shipbuilding:

The marine and shipbuilding industries employ planetary gears in various marine propulsion systems. They are used in marine engines, propeller systems, and thrusters. Planetary gears provide efficient power transmission, speed control, and compact design for propulsion systems in vessels ranging from small boats to large ships.

- Medical Equipment:

In the medical field, planetary gears are utilized in various equipment and devices. They are found in medical imaging systems like CT scanners and MRI machines, providing precise motion control and reducing image distortion. Planetary gears are also used in surgical robots and medical devices that require compact size, high torque, and accurate positioning.

These are just a few examples of the industries that commonly use planetary gears in their applications. The versatility, efficiency, and compactness of planetary gears make them suitable for a broad range of industries where precise motion control, torque transmission, and space-saving design are essential requirements.

editor by CX 2023-09-12

China high quality Spur Gear Spiral Bevel Gear Pinion Gear Helical Gear Worm Gear High Precision Manufacturer Steel /Straight/Planetary/Transmission/Starter top gear

Product Description

Customer High Precision Manufacturer Steel /Pinion/Straight/Helical Spur

Planetary/Transmission/Starter/ CNC machining/Drive Gear

Our advantage:

*Specialization in CNC formulations of high precision and quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Online orders and production progress monitoring

*Excellent price-quality ratio

*Absolute confidentiality

*Various materials (stainless steel, iron, brass, aluminum, titanium, special steels, industrial plastics)

*Manufacturing of complex components of 1 – 1000mm.

Production machine:

| Specification | Material | Hardness |

| Z13 | Steel | HRC35-40 |

| Z16 | Steel | HRC35-40 |

| Z18 | Steel | HRC35-40 |

| Z20 | Steel | HRC35-40 |

| Z26 | Steel | HRC35-40 |

| Z28 | Steel | HRC35-40 |

| Custom dimensions according to drawings | Steel | HRC35-40 |

Production machine:

Inspection equipment :

Gear tester

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in high-torque applications?

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

Can planetary gears be used in robotics and automation?

Planetary gears are commonly used in robotics and automation due to their numerous advantages and suitability for various applications. Let’s explore how planetary gears are utilized in robotics and automation:

- Compact Size and High Power Density:

Planetary gears offer a high power density, meaning they can transmit significant torque in a compact size. This characteristic is particularly valuable in robotics and automation systems, where space is often limited. The compactness of planetary gears allows for efficient integration into robotic joints, gearboxes, and other motion control components.

- Precision and Repeatability:

Planetary gears provide high precision and repeatability, making them suitable for precise positioning and motion control tasks in robotics and automation. The gear design and arrangement contribute to minimal backlash and accurate torque transmission, ensuring precise and predictable movements. This precision is essential in applications such as robotic arms, CNC machines, and pick-and-place systems.

- Speed Reduction and Torque Amplification:

Planetary gears offer the capability of speed reduction and torque amplification, allowing robots to handle varying loads and achieve different levels of speed and force. By utilizing the gear ratios and multiple gear stages, planetary gears enable robots to perform tasks that require both high torque and precise movements, such as lifting heavy objects or performing delicate assembly operations.

- Efficiency and Energy Savings:

Planetary gears are known for their high efficiency in power transmission. The gear design minimizes friction and ensures efficient torque transfer, resulting in reduced energy consumption. In robotics and automation, where energy efficiency is often a concern, the use of planetary gears can contribute to overall energy savings and longer battery life in battery-powered systems.

- Reliability and Durability:

Planetary gears are designed to be robust and durable, capable of withstanding demanding operating conditions. They can handle high loads, provide long service life, and resist wear and fatigue. These characteristics are crucial in robotics and automation, where the gears are subjected to repetitive and continuous motion. The reliability and durability of planetary gears contribute to the overall performance and longevity of robotic systems.

- Versatility and Customization:

Planetary gears offer versatility and customization options to meet specific requirements in robotics and automation. They can be combined with other mechanical components such as motors, encoders, and sensors to create tailored motion control systems. The ability to select different gear ratios, sizes, and configurations allows for the optimization of robotic designs for specific applications and performance criteria.

In summary, planetary gears are widely used in robotics and automation due to their compact size, high power density, precision, repeatability, speed reduction, torque amplification, efficiency, reliability, durability, versatility, and customization options. These qualities make planetary gears an excellent choice for various robotic applications, including industrial automation, collaborative robots, robotic prosthetics, unmanned vehicles, and many others.

What is a planetary gear and how does it work in mechanical systems?

A planetary gear, also known as an epicyclic gear, is a type of gear system used in mechanical systems to achieve various gear ratios and torque transmission. Let’s explore what a planetary gear is and how it works:

- Definition:

A planetary gear consists of three main components: a sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source, such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Operation:

When the sun gear rotates, it drives the planet gears, causing them to rotate on their own axes while also orbiting around the sun gear. The planet gears are mounted on the carrier, which can rotate independently or be held stationary. As the planet gears rotate and orbit, they engage with the ring gear, which remains fixed or acts as the output. This interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and torque transmission.

- Gear Ratios:

A key advantage of planetary gears is their ability to achieve multiple gear ratios within a compact design. By varying the number of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained. The gear ratio is determined by the ratio of the number of teeth between the sun gear and the ring gear, as well as the speed and direction of rotation of the sun gear.

- Applications:

Planetary gears are widely used in various mechanical systems and applications where precise control of speed, torque, and direction is required. They are commonly found in automotive transmissions, robotics, aerospace systems, industrial machinery, and more. Their compact size, high gear ratios, and torque-carrying capacity make them versatile and efficient in transmitting power.

In summary, a planetary gear is a gear system consisting of a sun gear, planet gears, and a ring gear. It operates by the rotation and orbiting of the planet gears around the sun gear, allowing for different gear ratios and torque transmission. Planetary gears find applications in a wide range of mechanical systems where precise control and efficient power transmission are necessary.

editor by CX 2023-09-12

China supplier Heavy Truck Transmission Planetary Gear Synchro Cone 1296333050/1296 333 050 with Good quality

Product Description

|

OE Number |

1296333050 |

|

Description |

Synchronizer Cone |

|

Applicable truck |

16S |

|

Technology |

Germany Technology |

|

Similar Products |

Products for G60/ G85 |

|

Our Range |

Gearbox Assembly, Parts, etc |

Who are we?

The most professional truck and spare parts manufacturer in China;

The leading truck and spare parts exporter in China;

The most comprehensive truck and spare parts solution provider in China;

The most worry-free and most satisfactory and reputable supplier for you in China.

We can never let you down if you choose us.

Real reviews from our customers

FAQ

Q1: Can you also supply Heavy Truck parts?

A1: Yes, We specialize in Sinotruk, Shacman, such as HOWO, CZPT F3000,F2000, etc.

Q2: What’s the MOQ?

A2: Usually MOQ is according to different products,5 -10PCS/model for stock items.

Q3: What’s the delivery time?

A3: It takes 5-7 days if there is stock, and takes 1 month if there is no stock.

Q4: What’s the payment term?

A4: All by T/T, 30% in advance, 70% balance before shipping; option: L/C at sight.

Q5: What’s the packaging?

A5: Neutral packing or customer make packing

Our Services

– OEM Manufacturing is welcome: Product, Package…

– Customized design exclusive sealing products

– Specially designed for SINOTRUK, CZPT series

– Installation guide

– Product maintenance training

– Free sample for your test

– We will reply your inquiry in 24 hours

| Application: | Electric Cars, Car, Truck Parts |

|---|---|

| Function: | Distribution Power, Change Drive Direction |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in high-torque applications?

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

Can planetary gears be used in robotics and automation?

Planetary gears are commonly used in robotics and automation due to their numerous advantages and suitability for various applications. Let’s explore how planetary gears are utilized in robotics and automation:

- Compact Size and High Power Density:

Planetary gears offer a high power density, meaning they can transmit significant torque in a compact size. This characteristic is particularly valuable in robotics and automation systems, where space is often limited. The compactness of planetary gears allows for efficient integration into robotic joints, gearboxes, and other motion control components.

- Precision and Repeatability:

Planetary gears provide high precision and repeatability, making them suitable for precise positioning and motion control tasks in robotics and automation. The gear design and arrangement contribute to minimal backlash and accurate torque transmission, ensuring precise and predictable movements. This precision is essential in applications such as robotic arms, CNC machines, and pick-and-place systems.

- Speed Reduction and Torque Amplification:

Planetary gears offer the capability of speed reduction and torque amplification, allowing robots to handle varying loads and achieve different levels of speed and force. By utilizing the gear ratios and multiple gear stages, planetary gears enable robots to perform tasks that require both high torque and precise movements, such as lifting heavy objects or performing delicate assembly operations.

- Efficiency and Energy Savings:

Planetary gears are known for their high efficiency in power transmission. The gear design minimizes friction and ensures efficient torque transfer, resulting in reduced energy consumption. In robotics and automation, where energy efficiency is often a concern, the use of planetary gears can contribute to overall energy savings and longer battery life in battery-powered systems.

- Reliability and Durability:

Planetary gears are designed to be robust and durable, capable of withstanding demanding operating conditions. They can handle high loads, provide long service life, and resist wear and fatigue. These characteristics are crucial in robotics and automation, where the gears are subjected to repetitive and continuous motion. The reliability and durability of planetary gears contribute to the overall performance and longevity of robotic systems.

- Versatility and Customization:

Planetary gears offer versatility and customization options to meet specific requirements in robotics and automation. They can be combined with other mechanical components such as motors, encoders, and sensors to create tailored motion control systems. The ability to select different gear ratios, sizes, and configurations allows for the optimization of robotic designs for specific applications and performance criteria.

In summary, planetary gears are widely used in robotics and automation due to their compact size, high power density, precision, repeatability, speed reduction, torque amplification, efficiency, reliability, durability, versatility, and customization options. These qualities make planetary gears an excellent choice for various robotic applications, including industrial automation, collaborative robots, robotic prosthetics, unmanned vehicles, and many others.

What is the purpose of using planetary gears in machinery?

Planetary gears serve several important purposes in machinery and mechanical systems. Let’s delve into the key purposes and benefits of using planetary gears:

- Gear Ratio Variation:

One of the primary purposes of planetary gears is to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. This flexibility enables machinery to adapt to varying speed and torque requirements, allowing for precise control and efficient power transmission.

- Torque Amplification:

Planetary gears are known for their ability to amplify torque. The arrangement of multiple gear sets in a compact design allows for torque multiplication. This can be particularly beneficial in applications where high torque is required while maintaining a smaller form factor. Planetary gears can efficiently transmit torque and handle heavy loads.

- Compact Size:

Another advantage of planetary gears is their compact size. The internal gear meshing and the integration of multiple gear sets within a single gear system contribute to their space-saving design. This compactness is valuable in machinery where space constraints are a consideration, enabling the design of more compact and lightweight systems.

- High Efficiency:

Planetary gears are known for their high efficiency in power transmission. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. This efficiency is crucial in machinery where energy conservation and optimization are important factors.

- Directional Control:

Planetary gears allow for bidirectional power transmission. By controlling the direction of rotation of the input and output elements, the direction of rotation in the machinery can be easily changed. This feature is useful in applications that require reversing the direction of rotation or changing the rotational direction without the need for additional mechanisms.

- Shock Absorption:

The arrangement of multiple gears in a planetary gear system provides inherent shock-absorbing capabilities. The distributed load between the gear teeth helps to dampen vibrations and absorb shocks, contributing to smoother operation and reduced wear on the system components.

- Application Versatility:

Planetary gears find applications in a wide range of machinery and mechanical systems. They are commonly used in automotive transmissions, industrial machinery, robotics, aerospace systems, power generation equipment, and more. The versatility of planetary gears stems from their ability to provide precise control, compactness, high torque transmission, and efficient power transmission.

In summary, the purpose of using planetary gears in machinery is to achieve variable gear ratios, amplify torque, maintain compact size, ensure high efficiency in power transmission, enable bidirectional control, absorb shocks, and provide versatility for various applications. The unique characteristics of planetary gears make them valuable components in diverse machinery and mechanical systems.

editor by CX 2023-09-12

China Good quality Ring Gear/Pinion Gear/Helical Gear/Spiral Bevel Gear/Drive Gear/Planetary Gear/Spur Gears/Transmission Gear bevel gearbox

Product Description

Our advantage:

*Specialization in CNC formulations of high precision and quality

*Independent quality control department

*Control plan and process flow sheet for each batch

*Quality control in all whole production

*Meeting demands even for very small quantities or single units

*Short delivery times

*Online orders and production progress monitoring

*Excellent price-quality ratio

*Absolute confidentiality

*Various materials (stainless steel, iron, brass, aluminum, titanium, special steels, industrial plastics)

*Manufacturing of complex components of 1 – 1000mm.

Production machine:

| Specification | Material | Hardness |

| Z13 | Steel | HRC35-40 |

| Z16 | Steel | HRC35-40 |

| Z18 | Steel | HRC35-40 |

| Z20 | Steel | HRC35-40 |

| Z26 | Steel | HRC35-40 |

| Z28 | Steel | HRC35-40 |

| Custom dimensions according to drawings | Steel | HRC35-40 |

Production machine:

Inspection equipment :

Gear tester

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Steel |

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in automotive applications?

Planetary gears are widely used in various automotive applications due to their numerous advantages. Let’s explore how planetary gears can be utilized in the automotive industry:

- Automatic Transmissions:

One of the primary applications of planetary gears in automobiles is in automatic transmissions. Automatic transmissions use a combination of planetary gear sets to achieve different gear ratios, allowing for smooth and efficient shifting between gears. The compact size and high torque capacity of planetary gears make them well-suited for this purpose, providing reliable and efficient power transmission in vehicles.

- Four-Wheel Drive Systems:

Planetary gears are also employed in four-wheel drive systems, where they help distribute power between the front and rear wheels. By utilizing planetary gear arrangements, the torque can be split between the front and rear axles, providing improved traction and stability on various road conditions. This allows vehicles to have enhanced off-road capabilities and better performance in challenging driving situations.

- Hybrid and Electric Vehicles:

Planetary gears play a crucial role in hybrid and electric vehicle powertrains. In these vehicles, planetary gear sets are often used to combine the power from the internal combustion engine and the electric motor. The gear arrangement allows for seamless transitions between different power sources, enabling efficient energy management and optimized performance.

- Start-Stop Systems:

Start-stop systems, which automatically shut off the engine when the vehicle is stationary and restart it when needed, often incorporate planetary gears. These gears help engage and disengage the engine from the drivetrain smoothly, ensuring a quick and seamless transition between the engine’s off and on states. Planetary gears contribute to the overall efficiency and reliability of start-stop systems.

- Power Steering:

Some power steering systems in automobiles utilize planetary gears to provide assistance in steering. These gears help amplify the driver’s input torque, making steering easier and more responsive. The compact size and high torque capacity of planetary gears make them suitable for power steering applications.

In summary, planetary gears find extensive use in automotive applications, including automatic transmissions, four-wheel drive systems, hybrid and electric vehicle powertrains, start-stop systems, and power steering. Their compact size, high torque capacity, and ability to achieve multiple gear ratios make them well-suited for these applications, providing efficient power transmission, improved performance, and enhanced driving experience in vehicles.

How do planetary gears handle variations in tooth engagement during operation?

Planetary gears are designed to handle variations in tooth engagement during operation, ensuring smooth and reliable performance. Let’s explore how planetary gears address these variations:

- Tolerance for Misalignment:

Planetary gears are designed with a certain degree of tolerance for misalignment. This means that slight variations in tooth engagement due to manufacturing tolerances, assembly, or operating conditions are accommodated without causing significant impact on the gear system. The gear teeth are carefully designed with appropriate profiles, clearances, and backlash to allow for some degree of misalignment while maintaining proper functioning.

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load across multiple gear teeth. Each planet gear shares the load with the adjacent gears, reducing the stress on individual teeth and promoting even tooth engagement. This load distribution capability helps minimize localized wear, noise, and vibration, resulting in smoother and more efficient operation.

- Flexible Mounting and Support:

Planetary gears are often mounted on flexible support structures, such as bearings or flexible couplings. These components help absorb and compensate for small variations in tooth engagement during operation. The flexible mounting and support systems provide some degree of flexibility and compliance, allowing the gears to self-adjust and maintain proper tooth contact under varying operating conditions.

- Lubrication and Cooling:

Proper lubrication and cooling play a crucial role in handling variations in tooth engagement. Lubricants reduce friction and wear between gear teeth, ensuring smooth operation and minimizing the impact of tooth engagement variations. Additionally, effective cooling mechanisms help dissipate heat generated during operation, preventing excessive temperature rise that could affect the gear meshing performance.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques. This robust construction enhances the gear system’s ability to withstand variations in tooth engagement. By ensuring high-quality gear components, proper heat treatment, and stringent quality control, planetary gears are built to handle the dynamic loads and variations encountered during operation.

In summary, planetary gears handle variations in tooth engagement through their tolerance for misalignment, load distribution among multiple planet gears, flexible mounting and support, effective lubrication and cooling, and robust construction. These design considerations and features enable planetary gears to maintain proper tooth contact, minimize wear and noise, and ensure reliable performance in various applications, including automotive transmissions, industrial machinery, and power transmission systems.

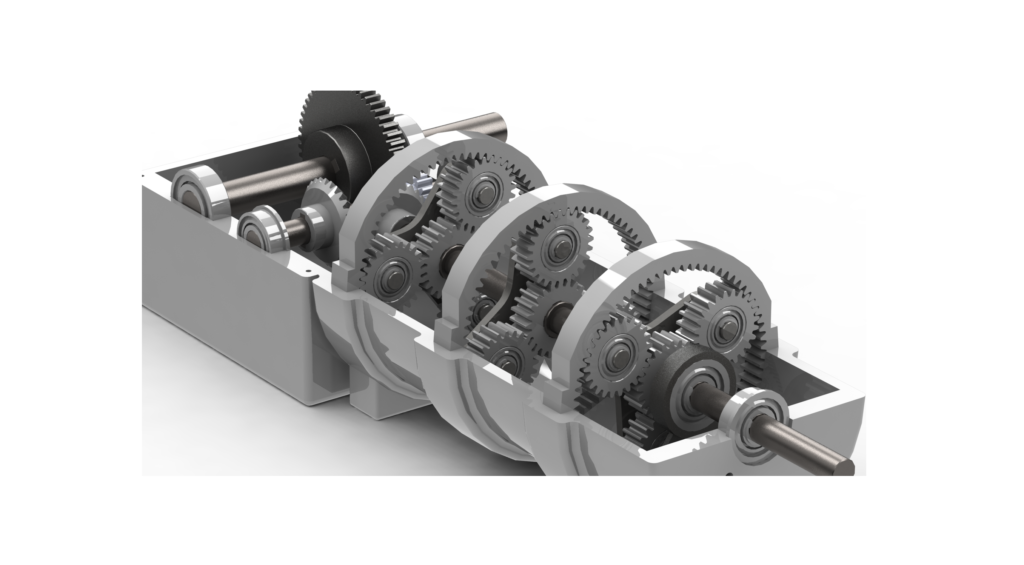

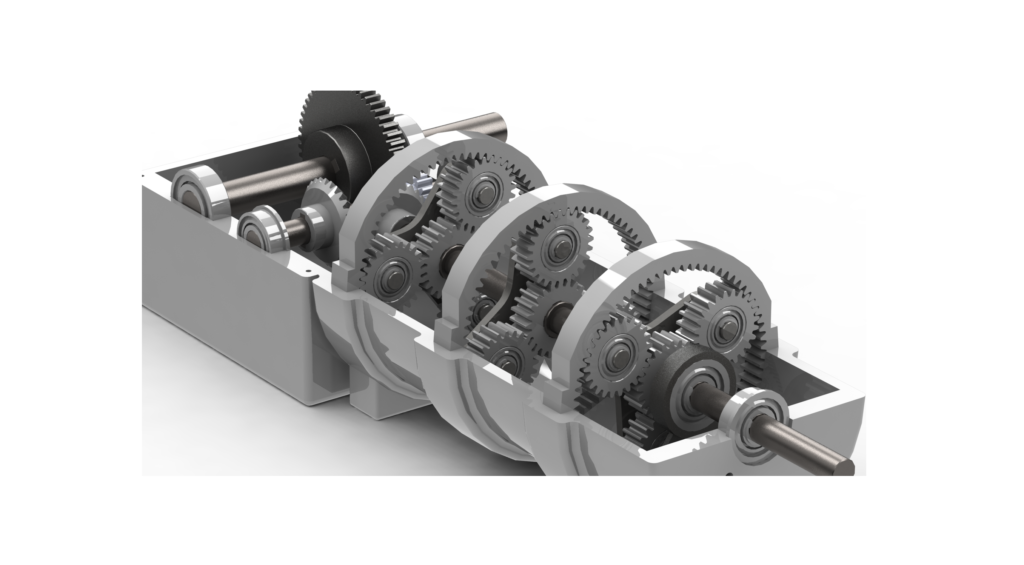

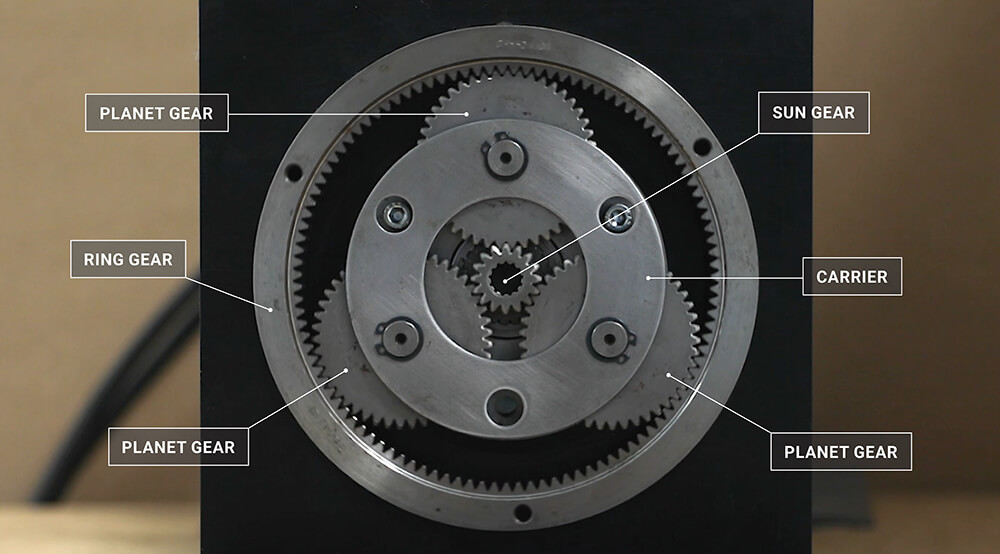

Can you explain the unique design and structure of planetary gears?

Planetary gears possess a unique design and structure that sets them apart from other gear systems. Let’s explore the distinctive features of the design and structure of planetary gears:

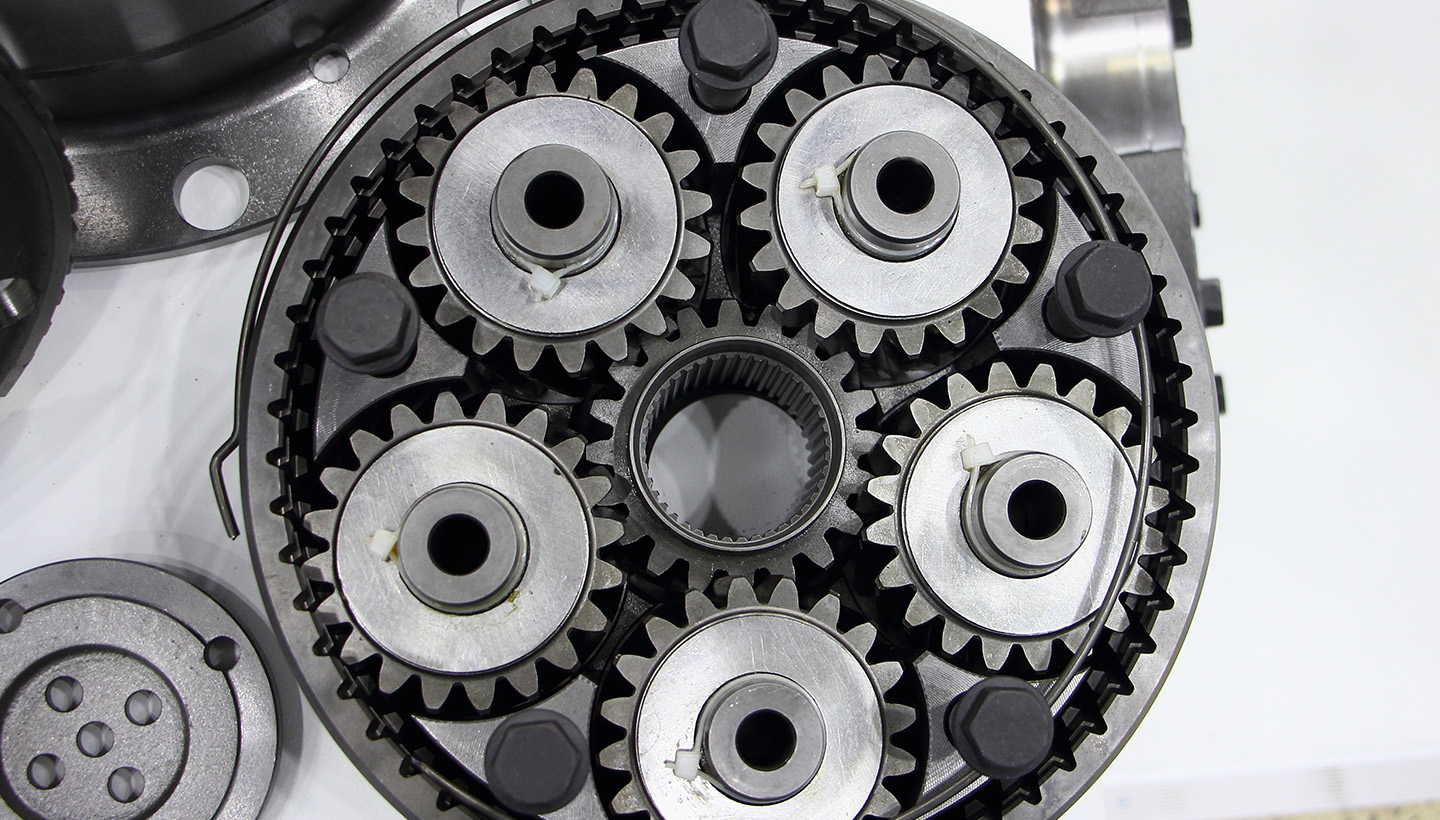

- Components:

A planetary gear system consists of three main components: the sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Internal Gear Meshing:

One of the distinguishing features of planetary gears is their internal gear meshing. Unlike other gear systems where the gears mesh externally, the teeth of the sun gear, planet gears, and ring gear are located on the inside surfaces. This arrangement allows for a compact and space-efficient design.

- Orbiting Motion:

In planetary gears, the planet gears exhibit both rotational and orbital motion. While they rotate on their own axes, they also orbit around the sun gear. This combination of rotational and orbital movement enables the gear system to achieve different gear ratios and torque transmission.

- Central Sun Gear: