Product Description

1) According to the different strength and performance, we choose the steel with strong compression;

2) Using Germany professional software and our professional engineers to design products with more reasonable size and better performance; 3) We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;

4) Quality assurance in every step to ensure product quality is controllable.

Product Paramenters

| DRIVEN GEAR |

NUMBER OF TEETH |

8 |

|

MODULE |

9.8718 | |

|

LENTH |

269 | |

|

OUTER DIAMETER |

ø111 |

|

|

DIRECTION OF SPIRAL |

L |

|

|

ACCURACY OF SPLINE |

M30*1.5-6g | |

|

NUMBER OF SPLINE |

16 |

|

DRIVEN GEAR |

NUMBER OF TEETH |

39 |

|

OUTER DIAMETER |

ø380 |

|

|

DIAMETER OF INNER HOLE |

ø244 |

|

|

ACCURACY OF SCREW |

12-M18*1.5-6H | |

|

CENTER DISTANCE OF SCREW HOLE |

ø290 |

|

|

DIRECTION OF SPIRAL |

R |

Company Profiles

Our company,HangZhou CHINAMFG Gear co.,Ltd , specialized in Hypoid and spiral bevel gear used in Automotive industry, was foundeded in 1996, with registered capital 136,8 square meter, with building area of 72,000 square meters. More than 500 employees work in our company.

We own more than 560 high-precise machining equipments, 10 Klingelnberg Oerlikon gear production lines, 36 Gleason gear production lines, 5 forging production lines 2 german Aichilin and 5 CHINAMFG CHINAMFG advanced automatic continuous heat treatment production lines. With the introducing the advanced Oerlikon C50 and P65 measuring center, we enhence our technology level and improve our product quality a lot. We offer better quality and good after-sale service with low price, which insure the good reputation. With the concept of “for the people, by technology, creativity, for the society, transfering friendship, honest”, we are trying to provice the world-top level product.

Our aim is: CHINAMFG Gear,world class, Drive the world.

According to the different strength and performance, we choose the steel with strong compression;Using Germany professional software and our professional engineers to design products with more reasonable size and better performance;We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;Quality assurance in every step to ensure product quality is controllable.

Our company had full quality management system and had been certified by ISO9001:2000, QS-9000:1998, ISO/TS16949 , which insure the entrance of international market.

Certification & honors

Packaging & Shipping

Packaging Detail:standard package(carton ,wooden pallet).

Shipping:Support Sea freight. Accept FOB,EXW,FAS,DES.

Cooperative customers

HangZhou CHINAMFG Gear Co., Ltd. adheres to the concept of “people-oriented, prosper with science and technology; create high-quality products, contribute to the society; turn friendship, and contribute sincerely”, and will strive to create world automotive axle spiral bevel gear products.

1.Do you provide samples?

Yes,we can offer free sample but not pay the cost of freight.

2.What about OEM?

Yes,we can do OEM according to your requirements.

3.How about after-sales service?

We have excellent after-sales service if you have any quanlity problem,you can contact us anytime.

4.What about package?

Stardard package or customized package as requirements.

5.How to ensure the quanlity of the products?

We can provide raw meterial report,metallographic examination and the accuracy testing etc.

6.How long is your delivery time?

Genarally it is 4-7 days.If customized it will be take 20 days according to your quantity.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Herringbone Gear |

| Material: | Cast Steel |

| Samples: |

US$ 90/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

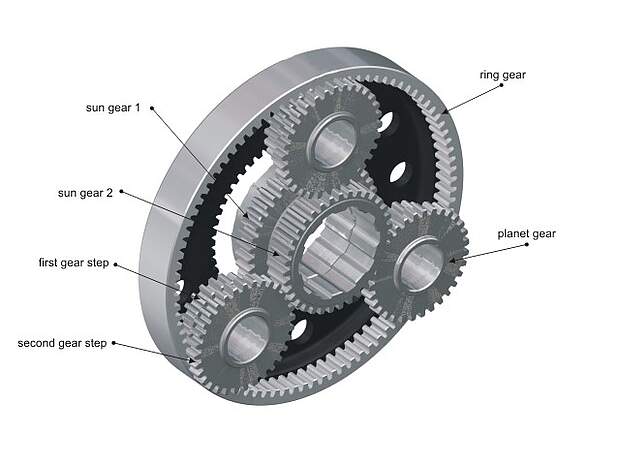

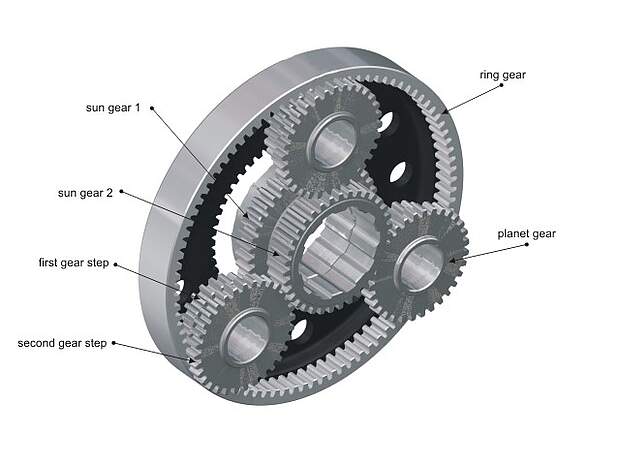

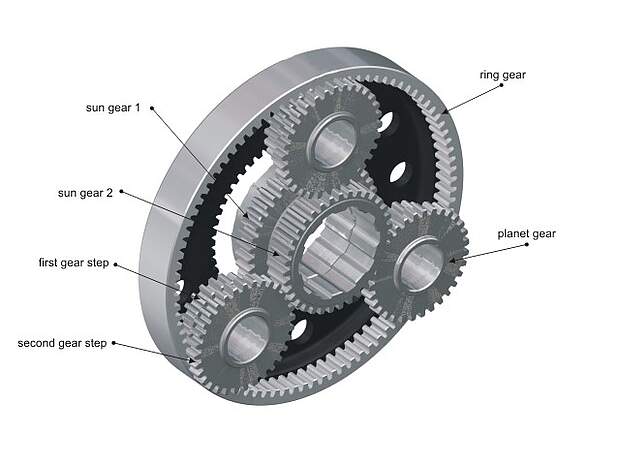

How does a planetary gear arrangement handle variations in load and stress?

A planetary gear arrangement offers inherent advantages in handling variations in load and stress. Let’s explore how it achieves this:

- Distributed Load:

One of the key advantages of a planetary gear arrangement is its ability to distribute the load among multiple gears. In this arrangement, the load is shared by the sun gear, planet gears, and ring gear, with each gear sharing a portion of the total load. As a result, the load on each individual gear is reduced compared to a single gear system, reducing stress concentration and enhancing the overall load-carrying capacity.

- Load Sharing:

Planet gears in a planetary gear system share the load as they are meshed with both the sun gear and the ring gear. This load-sharing characteristic ensures that the load is distributed evenly across multiple gear teeth and contact points. Consequently, the stress on each gear is reduced, minimizing the risk of tooth failure and increasing the system’s durability.

- Torque Splitting:

In a planetary gear arrangement, torque can be split among multiple paths. By controlling the distribution of torque between the sun gear and ring gear, variations in load can be managed effectively. If one gear path experiences higher stress, the torque distribution can be adjusted to shift the load to other gear paths, thereby balancing the stress and minimizing the risk of gear failure.

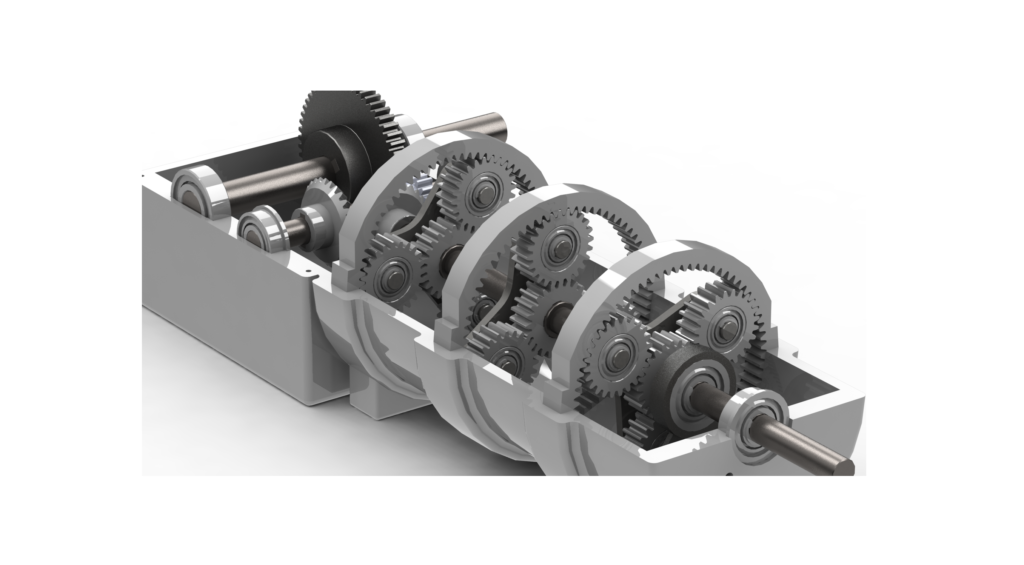

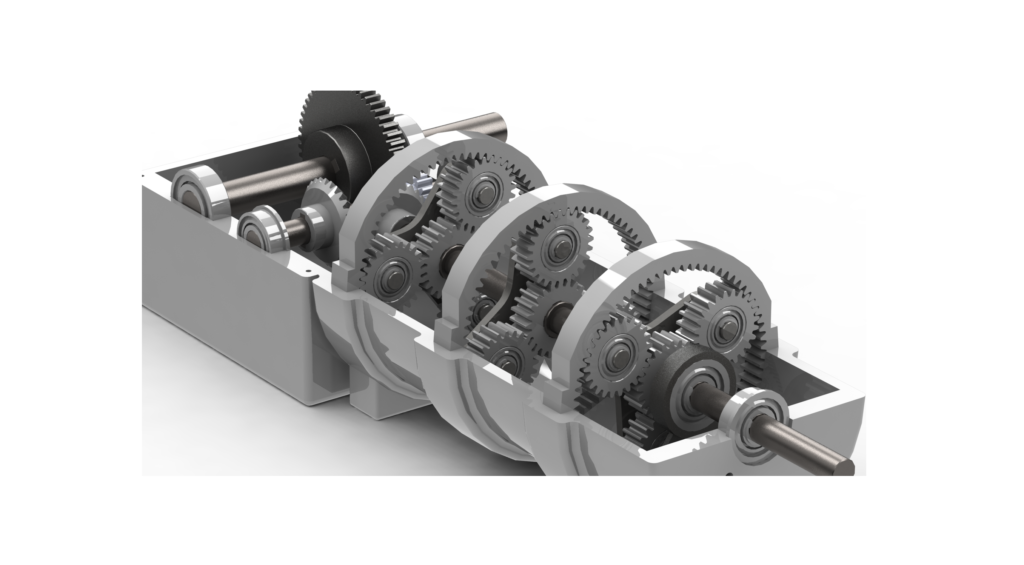

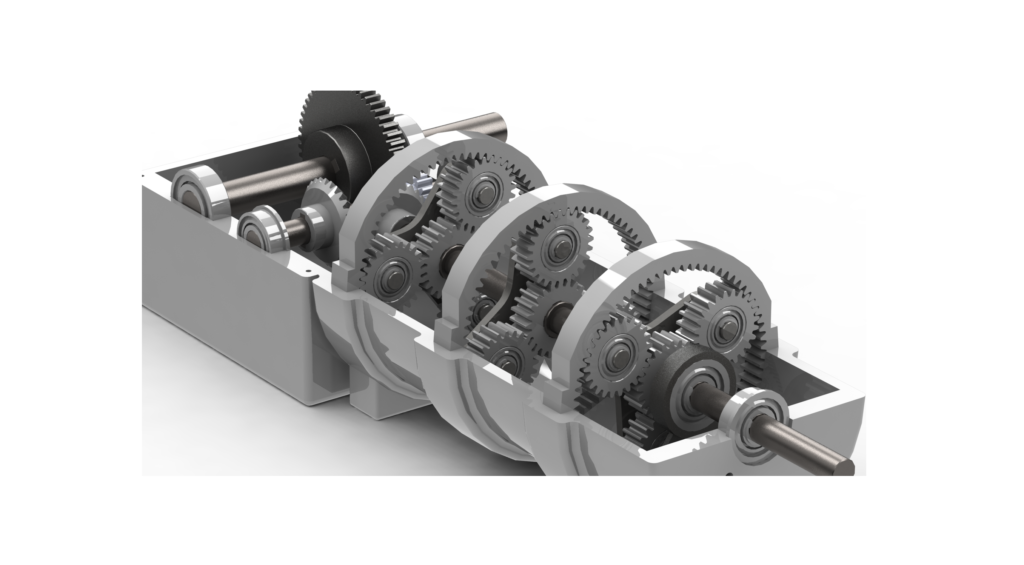

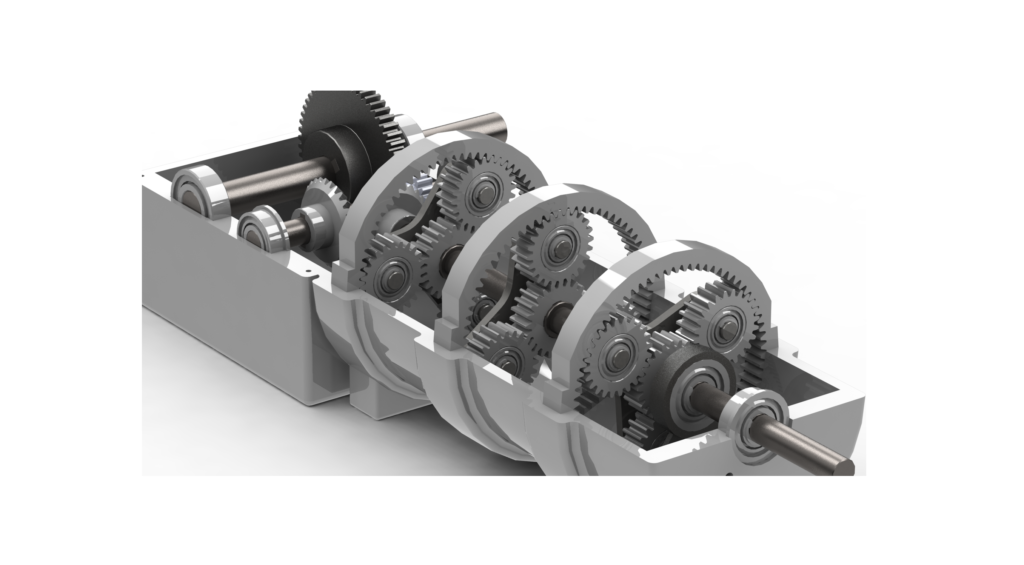

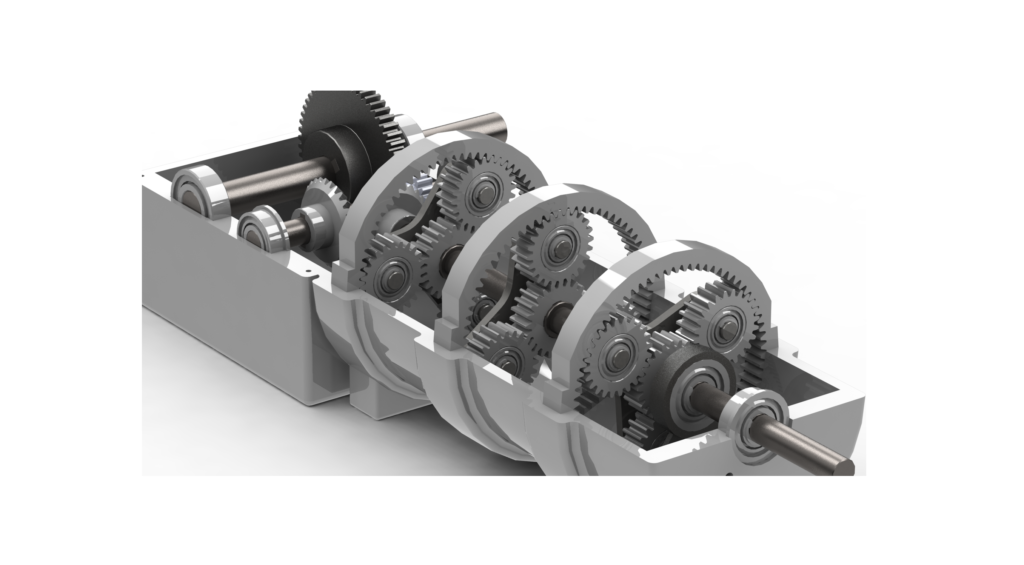

- Multiple Stages:

Planetary gear arrangements can be designed with multiple stages, involving multiple sets of sun gears, planet gears, and ring gears. Each stage can handle a portion of the load, allowing for further load distribution and stress reduction. This multi-stage configuration enhances the gear arrangement’s capacity to handle variations in load and stress, making it suitable for demanding applications.

- Robust Construction:

Planetary gear systems are known for their robust construction and high torque capacity. They are designed to withstand heavy loads and resist the effects of stress concentration. The use of high-quality materials and precise manufacturing techniques further enhances their ability to handle variations in load and stress.

In summary, a planetary gear arrangement handles variations in load and stress through distributed load sharing, torque splitting, multiple stages, and robust construction. By distributing the load among multiple gears, sharing the load between different paths, and employing multiple gear stages, a planetary gear arrangement can effectively manage variations in load and stress, ensuring reliable and durable operation in a wide range of applications.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature:

Monitor the operating temperature of the gear system. Excessive heat can degrade the lubricant’s performance and accelerate wear. Proper cooling mechanisms, such as fans or heat exchangers, may be required in high-temperature environments.

In summary, proper lubrication and maintenance are essential for planetary gears. Choose suitable lubricants, prevent contamination, follow recommended lubrication intervals, inspect for wear, ensure proper alignment, consider torque and load limits, monitor operating temperature, and conduct regular maintenance. By adhering to these considerations, you can prolong the lifespan, enhance performance, and minimize the risk of gear failure in planetary gear systems.

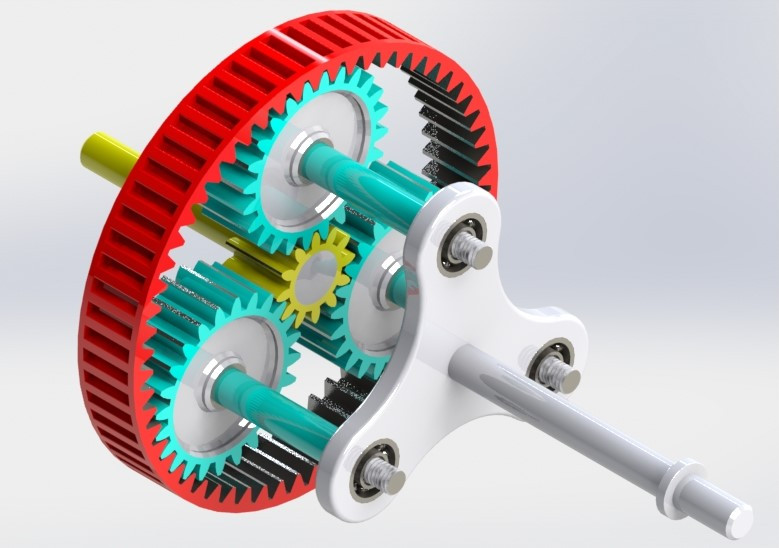

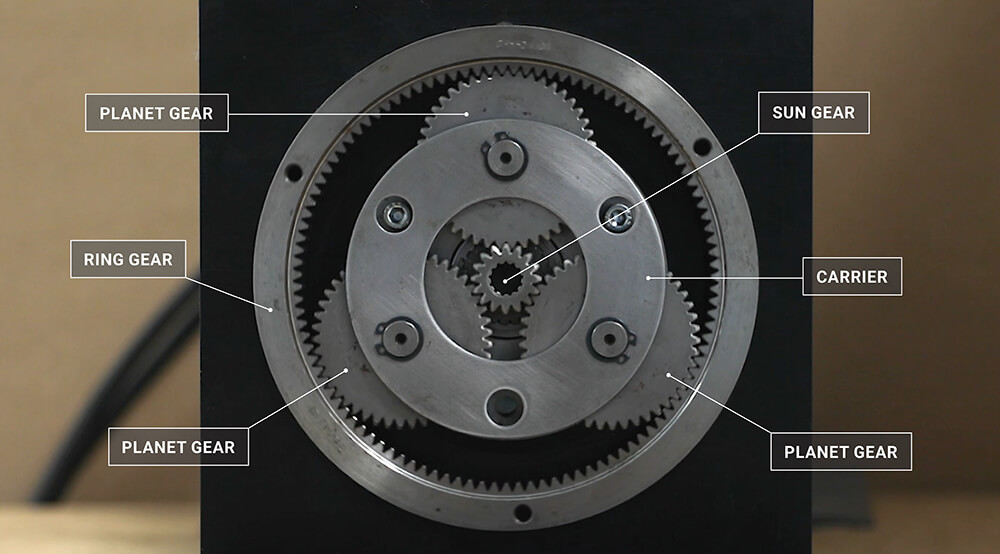

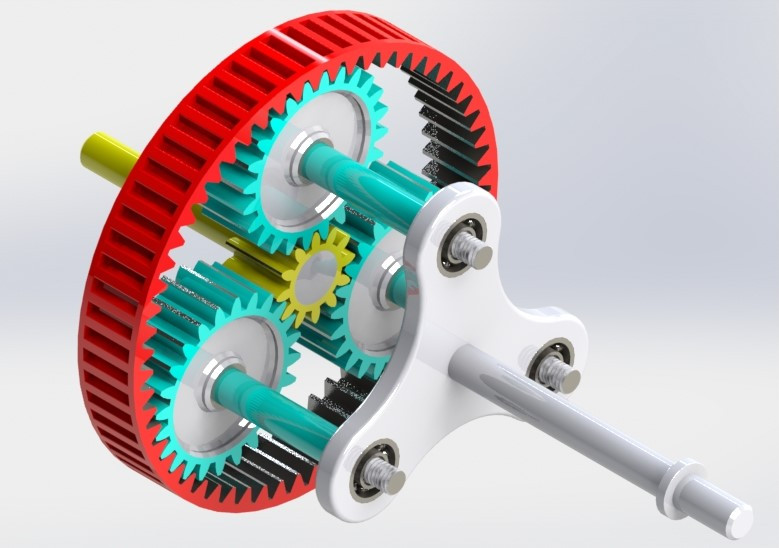

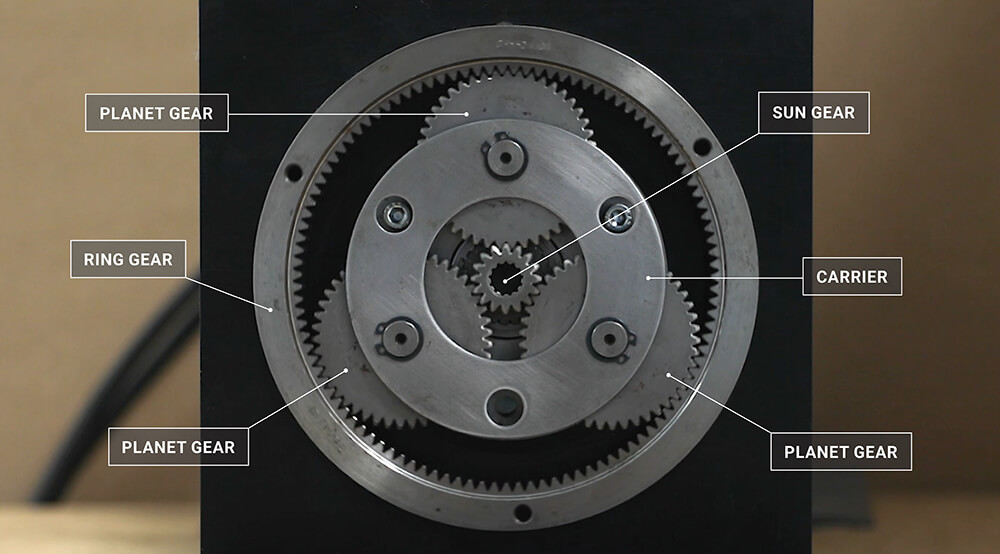

What is a planetary gear and how does it work in mechanical systems?

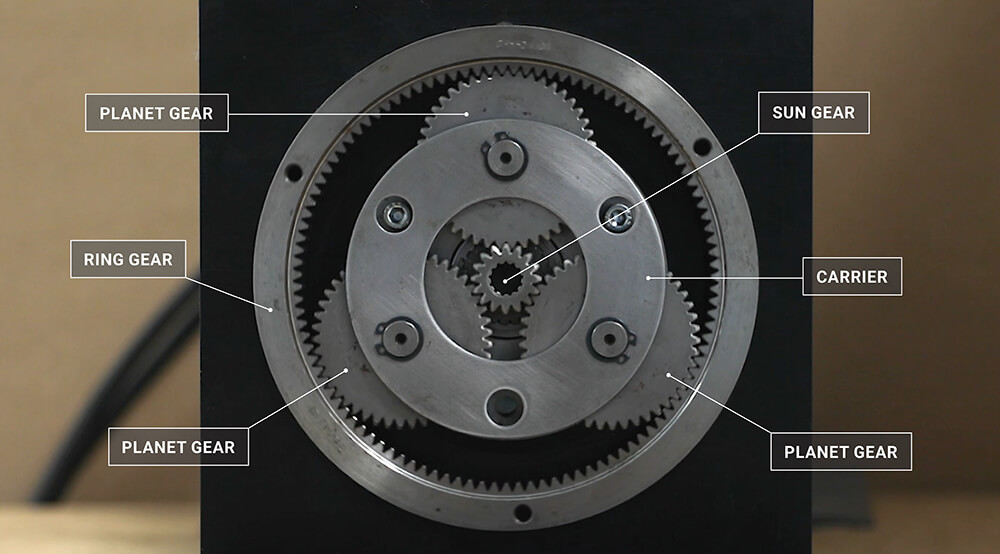

A planetary gear, also known as an epicyclic gear, is a type of gear system used in mechanical systems to achieve various gear ratios and torque transmission. Let’s explore what a planetary gear is and how it works:

- Definition:

A planetary gear consists of three main components: a sun gear, planet gears, and a ring gear. The sun gear is located at the center and is typically driven by an input source, such as a motor or engine. The planet gears are gears that surround the sun gear and are connected to a carrier or arm. The ring gear is the outermost gear and meshes with the planet gears.

- Operation:

When the sun gear rotates, it drives the planet gears, causing them to rotate on their own axes while also orbiting around the sun gear. The planet gears are mounted on the carrier, which can rotate independently or be held stationary. As the planet gears rotate and orbit, they engage with the ring gear, which remains fixed or acts as the output. This interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and torque transmission.

- Gear Ratios:

A key advantage of planetary gears is their ability to achieve multiple gear ratios within a compact design. By varying the number of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be obtained. The gear ratio is determined by the ratio of the number of teeth between the sun gear and the ring gear, as well as the speed and direction of rotation of the sun gear.

- Applications:

Planetary gears are widely used in various mechanical systems and applications where precise control of speed, torque, and direction is required. They are commonly found in automotive transmissions, robotics, aerospace systems, industrial machinery, and more. Their compact size, high gear ratios, and torque-carrying capacity make them versatile and efficient in transmitting power.

In summary, a planetary gear is a gear system consisting of a sun gear, planet gears, and a ring gear. It operates by the rotation and orbiting of the planet gears around the sun gear, allowing for different gear ratios and torque transmission. Planetary gears find applications in a wide range of mechanical systems where precise control and efficient power transmission are necessary.

editor by CX 2023-11-08

China supplier Swing Motor Cx210b Planetary Sun Gear Sm 2ND Krc10560 LC00149 for Cx160 Cx225sr Cx210b Cx220b Cx220c Excacator Parts with high quality

Product Description

Swing Motor CX210B Planetary Sun Gear SM 2nd KRC10560 LCA1 9571B 16571A1 9571B 16 0571 A1 CX130 16571A1 CX A1 9571B 161323A1 9030 155826A1 9030B 160560A1 CX210 431853A1 CX210B KRC1571 CX290 KSC5710 CX330 KSC5717

Hyundai

R180LC-3 RG08S-172-01 R2 EC210 7118-35710 EC210B 14541069 EC330 1055-0571 EC330B 1055-0571 EC360 1055-0571 EC360B 1055-0571

Sumitomo

SH120 KNC0087 SH200-5 KRC1571 SH300A-5 KSC5717

Kato

HD700SEV HD800V2 HD820-II

JCB

JS130 KNC0051 JS130 LNM571 LS-2650C-II KNC0037 2650Q KNC0051 2650Q LNM571 130LX KMC0078 130LX LNM571 2700Q LNM0449

CAT

312B 114-8226 320B 320C 148-4644 320L 7Y-1566 322C 191-2693 324D 325C 325B 110-7215 325D 329D 330B 114-1305 330C 330D 330L 199-4539 345D 296-6249

Kobelco

SK60V YRW00002F1 SK70SR YT32W00002F1 SK80CS YT32W00002F2 SK115SR YX32W00002F1 SK135SR YX32W00002F2 SK135SR-2 YY32W00004F1 SK200-8 YN32W00571F2 SK210-6 YN32W00571F1 SK330-6 LC32W00011F1 SK350-8 LC32W00011F1

Komatsu

PC60-5-6-7, PC100, PC120-5-6-7, PC130-5-6-7, PC150-6, PC160, PC180, PC200-1-3-5-6-7, PC200LC-7, PC210LC-6, PC220-1-3-5, PC220-7, PC228, PC250-6, PC270LC-6, PC280, PC300-3-5-6-7, PC350, PC4001-3-5

Hitachi

EX40, EX60, EX150, EX100M, EX100, EX120, EX150, EX200-1-2-3, EX300-1-3-5, EX400, UH08, UH07 ZX55 ZX60 ZX70 ZX110 ZX120 ZX130 ZX160 ZX200 ZX210 ZX240 ZX270 ZX330 ZX350 ZX450

Parts Details

Our Advantages

Main Products

| Brand: | Komatsu , , CHINAMFG , Vol Vo , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG 3CX 4CX Backhoe Loader |

| egory: | Spare Parts: |

| Advantaged Products: | Excavator Hydraulic Pump , Swing Motor Assy , Travel Motor Assy , Turbocharger , Water Pump , Main&Relief Valve Group … |

| Electrical Parts: | Excavator Solenoid Valve , Sensor , Switch , Controller , Monitor , Accelerator , Stater Motor , Alternator , Wipper Motor , Lamp , Water Tank …. |

| Engine Parts: | Excavator Engine Assy , Cylinder Head , Cylinder Block , Crankshaft , Camshaft , Linner Kits ( Piston / Piston Ring / Linner / Bearing ) , Gasket Kits , Overhaul Kits , Connecting Rod , Valve , Injector… |

| Cooling Parts: | Excavator Hydraulic Oil Cooler , Radiator , Oil Cooler Cover , Oil Cooler Assy , Fan , Blower Motor, EGR Pipe , Valve Chamber Cover… |

| Rubber Parts: | Excavator O-Ring , Seal Kits , Floor Mate Rubber , Coupling , Engine Belt , Belt Tensioner… |

| Hose & Harness Parts: | Excavator Pipe In , Manifold Exhaust , Water Hose , Oil Tube , Cabin Harness , Engine Harness… |

| Filtering Parts: | Excavator Oil Filter , Fuel Filter , Air Filter , Oil Separator , Air Filter Cover … |

Customer high Praise

Company Profile

Xihu (West Lake) Dis.an Machine Equipment Co., Ltd.( KOKO SHOP)

HangZhou Xihu (West Lake) Dis.an Machinery Equipment Co., Ltd. Our company was established in 2011.

Xihu (West Lake) Dis.an is a professional spare parts manufacturer and reliable supplier, providing almost all spare parts for various models rock breakers.

Specializes in:

Excavator accessories

Hydraulic breaker accessories

Breaker Spare Parts Suitable for the brands: SOOSAN, FURUKAWA, KRUPP, ATLAS-COPCO, EDT, JCB, NPK, , HANWOO, TOKU, FINE, OKADA, XIHU (WEST LAKE) DIS., MONTABERT, INDECO, KWANGLIM, RAMMER, KONAN, KOMATSU, GENERAL etc. Excavator Spare Parts Suitable for the brands: CATEE, KOMATSU, HITACHI, VOLVO, KOBELCO, CASE, SUMITOMO, DOOSA, NHYUNDAI, SANY, XG ect. The logistics in HangZhou is very convenient that we deliver goods to the whole world.

| After-sales Service: | Online |

|---|---|

| Warranty: | Online |

| Type: | Wheel Excavator |

| Usage: | Special Excavator, Marine Excavator, Mining Excavator, GM Excavator |

| Bucket: | Backhoe |

| Transmission: | Hydraulic Transmission |

| Customization: |

Available

| Customized Request |

|---|

How do you calculate the gear ratio involving sun, planet, and ring gears?

The gear ratio in a planetary gear system can be calculated by considering the number of teeth on the sun gear, planet gears, and ring gear. The gear ratio determines the relationship between the input speed and the output speed of the system. Here’s how you can calculate the gear ratio:

- Step 1: Count the Teeth:

Count the number of teeth on the sun gear (S), the planet gears (P), and the ring gear (R). These numbers represent the respective gear’s tooth count.

- Step 2: Determine the Gear Arrangement:

Identify the gear arrangement. In a simple planetary gear system, the sun gear is at the center, surrounded by planet gears, and enclosed by the ring gear.

- Step 3: Calculate the Gear Ratio:

The gear ratio (GR) can be determined using the formula:

GR = (R + P) / S

Where:

- R represents the number of teeth on the ring gear

- P represents the number of teeth on the planet gears (assuming they have the same number of teeth)

- S represents the number of teeth on the sun gear

The resulting gear ratio represents the speed relationship between the input and output of the planetary gear system. A gear ratio greater than 1 indicates a speed reduction, while a gear ratio less than 1 indicates a speed increase.

It’s important to note that in more complex planetary gear systems, where there are multiple sets of planet gears or additional gears, the calculation of the gear ratio may involve considering multiple gear stages and their respective tooth counts.

In summary, to calculate the gear ratio involving sun, planet, and ring gears, you need to count the teeth on each gear and use the formula (R + P) / S, where R is the number of teeth on the ring gear, P is the number of teeth on the planet gears, and S is the number of teeth on the sun gear. This calculation provides the gear ratio that defines the speed relationship between the input and output of the planetary gear system.

Can you explain the process of gear shifting in planetary gear systems?

Gear shifting in planetary gear systems involves changing the gear ratio by engaging or disengaging specific components of the gear set. Let’s explore the process of gear shifting in more detail:

- Clutching and Braking:

The gear shifting process in planetary gear systems primarily relies on clutching and braking mechanisms. These mechanisms selectively connect or disconnect various gears within the system to achieve the desired gear ratio. Here are the key steps involved:

- Clutch Engagement:

To shift to a higher gear ratio, the clutch associated with the gear component that needs to be engaged is activated. The clutch connects the rotating member, such as the sun gear, planet carrier, or ring gear, to the stationary member, allowing torque transmission. This engagement results in a change in the gear ratio, leading to higher speed or torque output depending on the specific gear set configuration.

- Brake Application:

On the other hand, to shift to a lower gear ratio, a brake associated with the gear component that needs to be disengaged is applied. The brake immobilizes or slows down the rotation of the selected gear element, preventing it from transmitting torque. By selectively braking certain components, the gear ratio is altered, resulting in a lower speed or higher torque output.

- Sequential Shifting:

In some planetary gear systems, gear shifting is performed sequentially. This means that one gear component is engaged or disengaged at a time, gradually transitioning from one gear ratio to another. Sequential shifting allows for smooth and controlled gear changes, minimizing the stress on the transmission components and ensuring seamless power transmission.

- Electronic Control:

In modern applications, gear shifting in planetary gear systems is often electronically controlled. Electronic control systems utilize sensors, actuators, and a control unit to monitor various parameters such as vehicle speed, engine load, and driver input. Based on these inputs, the control unit determines the optimal gear shift points and actuates the clutches and brakes accordingly. Electronic control enhances the efficiency, precision, and automation of the gear shifting process.

In summary, gear shifting in planetary gear systems involves the engagement and disengagement of clutches and brakes to alter the gear ratio. By selectively connecting or disconnecting specific gear components, the speed and torque output can be adjusted. Sequential shifting and electronic control systems further enhance the gear shifting process, providing smooth and efficient operation in various applications, including automotive transmissions and industrial machinery.

What industries commonly use planetary gears in their applications?

Planetary gears find applications in a wide range of industries and mechanical systems. Let’s explore some of the industries that commonly utilize planetary gears:

- Automotive Industry:

The automotive industry extensively uses planetary gears in various applications. Planetary gears are commonly found in automatic transmissions, where they enable smooth gear shifting, provide different gear ratios, and transmit torque efficiently. They are also used in differential systems, allowing wheels to rotate at different speeds while maintaining power distribution.

- Robotics and Automation:

Planetary gears play a crucial role in robotics and automation systems. They are employed in robotic joints and actuators to provide precise motion control, compact size, and high torque transmission. Planetary gears enable robotic arms to move accurately and handle heavy loads, making them essential components in industrial robots and robotic manipulators.

- Aerospace and Aviation:

The aerospace and aviation industries utilize planetary gears in various applications. They are used in aircraft landing gear systems, where they provide reliable torque transmission and compact design. Planetary gears are also employed in aircraft engine systems, helicopter rotor systems, and satellite mechanisms due to their efficiency, high torque capacity, and ability to operate in space-restricted environments.

- Power Generation:

Planetary gears are utilized in power generation equipment, including wind turbines and hydroelectric generators. In wind turbines, planetary gears enable the conversion of low-speed rotor rotation to high-speed generator rotation, ensuring efficient power generation. They are also employed in hydroelectric generators to transmit power from turbines to electrical generators, providing gear reduction and torque amplification.

- Industrial Machinery:

Planetary gears are widely used in industrial machinery applications. They are found in heavy-duty machinery such as mining equipment, construction machinery, and material handling systems. Planetary gears provide high torque transmission, compactness, and durability, making them suitable for handling demanding tasks in industrial environments.

- Marine and Shipbuilding:

The marine and shipbuilding industries employ planetary gears in various marine propulsion systems. They are used in marine engines, propeller systems, and thrusters. Planetary gears provide efficient power transmission, speed control, and compact design for propulsion systems in vessels ranging from small boats to large ships.

- Medical Equipment:

In the medical field, planetary gears are utilized in various equipment and devices. They are found in medical imaging systems like CT scanners and MRI machines, providing precise motion control and reducing image distortion. Planetary gears are also used in surgical robots and medical devices that require compact size, high torque, and accurate positioning.

These are just a few examples of the industries that commonly use planetary gears in their applications. The versatility, efficiency, and compactness of planetary gears make them suitable for a broad range of industries where precise motion control, torque transmission, and space-saving design are essential requirements.

editor by CX 2023-11-06

China supplier Desboer Geared Planetary Round Flange Ndv140 helical bevel gear

Product Description

Product Description

The NDV140 series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The ND series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: NDV140 Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

ultra-precision

Small size

Detailed Photos

Product Parameters

| Segment number | Single segment | ||||

| Ratio | i | 4 | 5 | 7 | 10 |

| Rated output torque | Nm | 530 | 610 | 520 | 420 |

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||

| Rated input speed | Rpm | 3000 | |||

| Max input speed | Rpm | 6000 | |||

| Ultraprecise backlash | arcmin | ≤1 | |||

| Precision backlash | arcmin | ≤3 | |||

| Standard backlash | arcmin | ≤5 | |||

| Torsional rigidity | Nm/arcmin | 151 | |||

| Max.bending moment | Nm | 1310 | |||

| Max.axial force | N | 8530 | |||

| Service life | hr | 30000(15000 under continuous operation) | |||

| Efficiency | % | ≥97% | |||

| Weight | kg | 11.9 | |||

| Operating Temperature | ºC | -10ºC~+90ºC | |||

| Lubrication | Synthetic grease | ||||

| Protection class | IP64 | ||||

| Mounting Position | All directions | ||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤65 | |||

| Rotary inertia | Kg·cm² | 7.54 | 7.42 | 7.14 | 7.03 |

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

Certifications

Company Profile

DESBOER (HangZhou) Transmission Technology Co., Ltd. is a subsidiary of DESBOER (China), which is committed to the design, development, customized production and sales of high precision planetary reducer as 1 of the technology company. Our company has over 10 years of design, production and sales experience, the main products are the high precision planetary reducer, gear, rack, etc., with high quality, short delivery period, high cost performance and other advantages to better serve the demand of global customers. It is worth noting that we remove the intermediate link sale from the factory directly to customers, so that you can get the most ideal price and also get our best quality service simultaneously.

About Research

In order to strengthen the advantages of products in the international market, the head company in Kyoto, Japan to established KABUSHIKIKAISYA KYOEKI, mainly engaged in the development of DESBOER high precision planetary reducer, high precision of transmission components such as the development work, to provide the most advanced design technology and the most high-quality products for the international market.

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in high-torque applications?

Yes, planetary gears are well-suited for high-torque applications due to their design characteristics and capabilities. Let’s explore why planetary gears can be used in high-torque applications:

- Torque Distribution:

Planetary gears are designed to distribute torque across multiple gear teeth, allowing them to handle higher torque loads. The arrangement of planet gears around the sun gear and meshing with the ring gear enables torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. As a result, planetary gears can effectively handle high torque loads without compromising performance or durability.

- High Torque Density:

Planetary gears offer high torque density, meaning they can transmit a significant amount of torque relative to their size and weight. The design of planetary gears allows for multiple gear teeth to engage simultaneously, distributing the load and increasing torque-carrying capacity. This high torque density makes planetary gears suitable for applications that require substantial torque output in compact spaces. They can handle the demands of high-torque requirements without the need for larger gear systems.

- Torque Amplification:

Planetary gears can also provide torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. This torque amplification feature is advantageous in high-torque applications where a higher output torque is desired while maintaining a smaller physical size. It enables planetary gears to deliver the necessary torque for demanding tasks.

- Load Sharing:

Another advantage of planetary gears in high-torque applications is load sharing. The planet gears distribute the load across multiple gear teeth, preventing concentrated stress on individual teeth. This load sharing capability minimizes the risk of gear failure and ensures the durability and longevity of the gear system. It allows planetary gears to handle high torque loads while maintaining reliable and efficient operation.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques to withstand high torque applications. The gear components are engineered to have sufficient strength and durability to handle the demanding conditions associated with high torque. This robust construction ensures that the planetary gears can reliably transmit and sustain high torque without experiencing premature wear or failure.

In summary, planetary gears can be effectively used in high-torque applications due to their torque distribution capabilities, high torque density, torque amplification, load sharing characteristics, and robust construction. These features make planetary gears a reliable choice for various industries, including heavy machinery, automotive drivetrains, industrial equipment, and more.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature:

Monitor the operating temperature of the gear system. Excessive heat can degrade the lubricant’s performance and accelerate wear. Proper cooling mechanisms, such as fans or heat exchangers, may be required in high-temperature environments.

In summary, proper lubrication and maintenance are essential for planetary gears. Choose suitable lubricants, prevent contamination, follow recommended lubrication intervals, inspect for wear, ensure proper alignment, consider torque and load limits, monitor operating temperature, and conduct regular maintenance. By adhering to these considerations, you can prolong the lifespan, enhance performance, and minimize the risk of gear failure in planetary gear systems.

What industries commonly use planetary gears in their applications?

Planetary gears find applications in a wide range of industries and mechanical systems. Let’s explore some of the industries that commonly utilize planetary gears:

- Automotive Industry:

The automotive industry extensively uses planetary gears in various applications. Planetary gears are commonly found in automatic transmissions, where they enable smooth gear shifting, provide different gear ratios, and transmit torque efficiently. They are also used in differential systems, allowing wheels to rotate at different speeds while maintaining power distribution.

- Robotics and Automation:

Planetary gears play a crucial role in robotics and automation systems. They are employed in robotic joints and actuators to provide precise motion control, compact size, and high torque transmission. Planetary gears enable robotic arms to move accurately and handle heavy loads, making them essential components in industrial robots and robotic manipulators.

- Aerospace and Aviation:

The aerospace and aviation industries utilize planetary gears in various applications. They are used in aircraft landing gear systems, where they provide reliable torque transmission and compact design. Planetary gears are also employed in aircraft engine systems, helicopter rotor systems, and satellite mechanisms due to their efficiency, high torque capacity, and ability to operate in space-restricted environments.

- Power Generation:

Planetary gears are utilized in power generation equipment, including wind turbines and hydroelectric generators. In wind turbines, planetary gears enable the conversion of low-speed rotor rotation to high-speed generator rotation, ensuring efficient power generation. They are also employed in hydroelectric generators to transmit power from turbines to electrical generators, providing gear reduction and torque amplification.

- Industrial Machinery:

Planetary gears are widely used in industrial machinery applications. They are found in heavy-duty machinery such as mining equipment, construction machinery, and material handling systems. Planetary gears provide high torque transmission, compactness, and durability, making them suitable for handling demanding tasks in industrial environments.

- Marine and Shipbuilding:

The marine and shipbuilding industries employ planetary gears in various marine propulsion systems. They are used in marine engines, propeller systems, and thrusters. Planetary gears provide efficient power transmission, speed control, and compact design for propulsion systems in vessels ranging from small boats to large ships.

- Medical Equipment:

In the medical field, planetary gears are utilized in various equipment and devices. They are found in medical imaging systems like CT scanners and MRI machines, providing precise motion control and reducing image distortion. Planetary gears are also used in surgical robots and medical devices that require compact size, high torque, and accurate positioning.

These are just a few examples of the industries that commonly use planetary gears in their applications. The versatility, efficiency, and compactness of planetary gears make them suitable for a broad range of industries where precise motion control, torque transmission, and space-saving design are essential requirements.

editor by CX 2023-11-06

China Hot selling Low Noise24V120W150W 72mm DC Brushless Motor with Planetary Gear Reduction straight bevel gear

Product Description

| BGBL72 DC Brushless Motor | |

| Environmental Conditions | -20ºC~50ºC |

| Insulation Clase | B |

| Protection class | IP40 |

| Noise | ≤65dB |

| Number of Poles/ phases | 3 |

| Lifespan | >5000h |

| Electrical Specifications | |||||||||

| Model | RATED LOAD | NO LOAD | STALL | ||||||

| Voltage | Power | Speed | Torque | Current | Speed | Current | Torque | Current | |

| V | W | rpm | N.m | A | rpm | A | N.m | A | |

| BG72BL24120 | 24 | 120 | 3000 | 0.382 | 6.6 | 4000 | 1 | 1.146 | 19.8 |

| BG72BL24150 | 24 | 150 | 3000 | 0.478 | 8.5 | 4000 | 1.1 | 1.434 | 25.5 |

| We can also customize products according to customer requirements. | |||||||||

| Planetary Gear Motor Technical Data-BG | |||||||||||||

| Ratio | 3.65 | 5.36 | 6.55 | 8.63 | 13.53 | 18.92 | 24.65 | 28.05 | 33.92 | 44.69 | 58.22 | 67.08 | 81.11 |

| Output shaft speed(rpm) | 822 | 560 | 458 | 348 | 222 | 159 | 122 | 107 | 88 | 67 | 52 | 45 | 37 |

| Allowable torque(N.m) | 1.25 | 1.84 | 2.25 | 2.97 | 4.19 | 5.85 | 7.63 | 8.68 | 10.5 | 13.83 | 18.01 | 18.71 | 22.62 |

| Reduction stage | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 |

Established in 1994, HangZhou BG Motor Factory is a professional manufacturer of brushless DC motors, brushed DC motors, planetary gear motors, worm gear motors, Universal motors and AC motors. We have a plant area of 6000 square meters, multiple patent certificates, and we have the independent design and development capabilities and strong technical force, with an annual output of more than 1 million units. Since the beginning of its establishment, BG motor has focused on the overall solution of motors. We manufacture and design motors, provide professional customized services, respond quickly to customer needs, and actively help customers to solve problems. Our motor products are exported to 20 countries, including the United States, Germany, Italy, the United Kingdom, Poland, Slovenia, Switzerland, Sweden, Singapore, South Korea etc.

Our founder, Mr. Sun, has more than 40 years of experience in motor technology, and our other engineers also have more than 15 years of experience, and 60% of our staff have more than 10 years of experience, and we can assure you that the quality of our motors is top notch.

The products cover AGV, underwater robots, robots, sewing machine industry, automobiles, medical equipment, automatic doors, lifting equipment, industrial equipment and have a wide range of applications.

We strive for CHINAMFG in the quality of each product, and we are only a small and sophisticated manufacturer.

Our vision: Drive the world CHINAMFG and make life better!

Q:1.What kind of motors can you provide?

A:At present, we mainly produce brushless DC motors, brush DC motors, AC motors, Universal Motors; the power of the motor is less than 5000W, and the diameter of the motor is not more than 200mm;

Q:2.Can you send me a price list?

A:For all of our motors, they are customized based on different requirements like lifetime, noise,voltage,and shaft etc. The price also varies according to annual quantity. So it’s really difficult for us to provide a price list. If you can share your detailed requirements and annual quantity, we’ll see what offer we can provide.

Q:3.Can l get some samples?

A:It depends. If only a few samples for personal use or replacement, I am afraid it’ll be difficult for us to provide because all of our motors are custom made and no stock available if there are no further needs. If just sample testing before the official order and our MOQ,price and other terms are acceptable,we’d love to provide samples.

Q4:Can you provide OEM or ODM service?

A:Yes,OEM and ODM are both available, we have the professional R&D dept which can provide professional solutions for you.

Q5:Can l visit your factory before we place an order?

A:welcome to visit our factory,wear every pleased if we have the chance to know each other more.

Q:6.What’s the lead time for a regular order?

A:For orders, the standard lead time is 15-20 days and this time can be shorter or longer based on the different model,period and quantity.

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools, Robot Arm |

|---|---|

| Operating Speed: | Low Speed |

| Excitation Mode: | DC |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Number of Poles: | Can Be Choosen |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do planetary gears handle changes in speed and torque distribution?

Planetary gears are capable of effectively handling changes in speed and torque distribution due to their unique design and configuration. Let’s explore how planetary gears handle these changes:

- Speed Changes:

Planetary gears can handle speed changes by utilizing the different gear ratios they offer. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. When the input speed is applied to the sun gear, it gets transmitted to the planet gears, resulting in a specific output speed. By changing the gear ratio, the output speed can be adjusted accordingly. This ability to vary the gear ratio allows planetary gears to adapt to different speed requirements in mechanical systems.

- Torque Distribution:

Planetary gears excel in distributing torque across multiple gear teeth, ensuring efficient torque transmission and load sharing. The planet gears are meshed with both the sun gear and the ring gear, enabling torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. The load is shared among the planet gears, preventing excessive wear and minimizing the risk of gear failure.

- Torque Amplification:

Planetary gears can also handle torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The arrangement of multiple gear sets in a compact design enables torque amplification, making planetary gears suitable for applications that require high torque output while maintaining a smaller physical size.

- Load Balancing:

Another aspect of torque distribution in planetary gears is load balancing. The planet gears distribute the load across multiple gear teeth, reducing the concentration of forces on individual teeth. This load balancing capability results in improved gear system durability and longevity. It also helps in minimizing vibration, noise, and wear, ensuring smoother and more reliable operation.

- Flexible Configuration:

Planetary gears offer flexibility in their configuration, allowing for the accommodation of changes in speed and torque distribution. The number of planet gears, the size of the gears, and their arrangement can be adjusted to meet specific application requirements. This flexibility enables planetary gears to handle a wide range of speed and torque variations, making them adaptable to different mechanical setups.

In summary, planetary gears handle changes in speed and torque distribution through their ability to adjust gear ratios, distribute torque across multiple gear teeth, amplify torque, balance loads, and accommodate flexible configurations. These characteristics make planetary gears suitable for applications that require precise control over speed and torque, efficient power transmission, and reliable performance.

Can planetary gears be used in robotics and automation?

Planetary gears are commonly used in robotics and automation due to their numerous advantages and suitability for various applications. Let’s explore how planetary gears are utilized in robotics and automation:

- Compact Size and High Power Density:

Planetary gears offer a high power density, meaning they can transmit significant torque in a compact size. This characteristic is particularly valuable in robotics and automation systems, where space is often limited. The compactness of planetary gears allows for efficient integration into robotic joints, gearboxes, and other motion control components.

- Precision and Repeatability:

Planetary gears provide high precision and repeatability, making them suitable for precise positioning and motion control tasks in robotics and automation. The gear design and arrangement contribute to minimal backlash and accurate torque transmission, ensuring precise and predictable movements. This precision is essential in applications such as robotic arms, CNC machines, and pick-and-place systems.

- Speed Reduction and Torque Amplification:

Planetary gears offer the capability of speed reduction and torque amplification, allowing robots to handle varying loads and achieve different levels of speed and force. By utilizing the gear ratios and multiple gear stages, planetary gears enable robots to perform tasks that require both high torque and precise movements, such as lifting heavy objects or performing delicate assembly operations.

- Efficiency and Energy Savings:

Planetary gears are known for their high efficiency in power transmission. The gear design minimizes friction and ensures efficient torque transfer, resulting in reduced energy consumption. In robotics and automation, where energy efficiency is often a concern, the use of planetary gears can contribute to overall energy savings and longer battery life in battery-powered systems.

- Reliability and Durability:

Planetary gears are designed to be robust and durable, capable of withstanding demanding operating conditions. They can handle high loads, provide long service life, and resist wear and fatigue. These characteristics are crucial in robotics and automation, where the gears are subjected to repetitive and continuous motion. The reliability and durability of planetary gears contribute to the overall performance and longevity of robotic systems.

- Versatility and Customization:

Planetary gears offer versatility and customization options to meet specific requirements in robotics and automation. They can be combined with other mechanical components such as motors, encoders, and sensors to create tailored motion control systems. The ability to select different gear ratios, sizes, and configurations allows for the optimization of robotic designs for specific applications and performance criteria.

In summary, planetary gears are widely used in robotics and automation due to their compact size, high power density, precision, repeatability, speed reduction, torque amplification, efficiency, reliability, durability, versatility, and customization options. These qualities make planetary gears an excellent choice for various robotic applications, including industrial automation, collaborative robots, robotic prosthetics, unmanned vehicles, and many others.

Can you describe the role of sun gears, planet gears, and ring gears in planetary systems?

In a planetary gear system, each component—the sun gear, planet gears, and ring gear—plays a crucial role in the overall operation and functionality. Let’s explore the roles of these gears:

- Sun Gear:

The sun gear is a central component in a planetary gear system. It is typically located at the center and is driven by an input source such as a motor or engine. The sun gear receives the input power and transmits it to the other gears in the system. As the sun gear rotates, it drives the rotation of the planet gears, which, in turn, contribute to the overall gear operation. The size and number of teeth on the sun gear determine the gear ratio and torque characteristics of the system.

- Planet Gears:

The planet gears are gears that surround the sun gear in a planetary gear system. They are typically smaller in size compared to the sun gear and are connected to a carrier or arm. The planet gears mesh with both the sun gear and the ring gear. As the sun gear rotates, it drives the rotation of the planet gears. The planet gears exhibit both rotational and orbital motion. While they rotate on their own axes, they also orbit around the sun gear. This combination of rotational and orbital movement allows the planet gears to transmit torque and contribute to the overall gear reduction or amplification. The arrangement and number of planet gears can vary depending on the specific design and requirements of the system.

- Ring Gear:

The ring gear is the outermost gear in a planetary gear system. It has internal teeth that mesh with the planet gears. The ring gear remains fixed or stationary while the sun gear and planet gears rotate. The interaction between the planet gears and the ring gear enables the gear system to achieve gear reduction or amplification. The size and number of teeth on the ring gear also influence the gear ratio and torque characteristics of the system.

In summary, the sun gear serves as the primary driver, receiving the input power and transmitting it to the other gears. The planet gears rotate and orbit around the sun gear, contributing to torque transmission and gear functionality. The ring gear remains fixed and meshes with the planet gears, allowing for gear reduction or amplification. Together, these gears work in harmony to achieve the desired gear ratios, torque transmission, and overall operation of planetary gear systems.

editor by CX 2023-11-06

China wholesaler China Factory OEM Sintered Metal Powder Steel Spur Pinion Sintered Gear/Planetary Gear/Bevel Gear/Worm Gear with Hot selling

Product Description

Sintered spur metal small gear

Why Powdered Metals?

Significant cost savings.

Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials.

Production process of powder metallurgy

Powder mixing – Forming – Sintering – Oil impregnation – Sizing -Ultrasonic cleaning – Steam oxidation – Oil impregnation – Final inspection – Packing

Company Profile

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the “More diversity, More superior, More professional ” business purposes, we are committed to establish long-term friendship and CHINAMFG relationship with domestic and international customers to create a bright future .

Certification

Just contact with us with 2D or 3D drawing to start our cooperation!

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Sintered Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Iron |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does a planetary gear arrangement handle variations in load and stress?

A planetary gear arrangement offers inherent advantages in handling variations in load and stress. Let’s explore how it achieves this:

- Distributed Load:

One of the key advantages of a planetary gear arrangement is its ability to distribute the load among multiple gears. In this arrangement, the load is shared by the sun gear, planet gears, and ring gear, with each gear sharing a portion of the total load. As a result, the load on each individual gear is reduced compared to a single gear system, reducing stress concentration and enhancing the overall load-carrying capacity.

- Load Sharing:

Planet gears in a planetary gear system share the load as they are meshed with both the sun gear and the ring gear. This load-sharing characteristic ensures that the load is distributed evenly across multiple gear teeth and contact points. Consequently, the stress on each gear is reduced, minimizing the risk of tooth failure and increasing the system’s durability.

- Torque Splitting:

In a planetary gear arrangement, torque can be split among multiple paths. By controlling the distribution of torque between the sun gear and ring gear, variations in load can be managed effectively. If one gear path experiences higher stress, the torque distribution can be adjusted to shift the load to other gear paths, thereby balancing the stress and minimizing the risk of gear failure.

- Multiple Stages:

Planetary gear arrangements can be designed with multiple stages, involving multiple sets of sun gears, planet gears, and ring gears. Each stage can handle a portion of the load, allowing for further load distribution and stress reduction. This multi-stage configuration enhances the gear arrangement’s capacity to handle variations in load and stress, making it suitable for demanding applications.

- Robust Construction:

Planetary gear systems are known for their robust construction and high torque capacity. They are designed to withstand heavy loads and resist the effects of stress concentration. The use of high-quality materials and precise manufacturing techniques further enhances their ability to handle variations in load and stress.

In summary, a planetary gear arrangement handles variations in load and stress through distributed load sharing, torque splitting, multiple stages, and robust construction. By distributing the load among multiple gears, sharing the load between different paths, and employing multiple gear stages, a planetary gear arrangement can effectively manage variations in load and stress, ensuring reliable and durable operation in a wide range of applications.

Can you explain the process of gear shifting in planetary gear systems?

Gear shifting in planetary gear systems involves changing the gear ratio by engaging or disengaging specific components of the gear set. Let’s explore the process of gear shifting in more detail:

- Clutching and Braking:

The gear shifting process in planetary gear systems primarily relies on clutching and braking mechanisms. These mechanisms selectively connect or disconnect various gears within the system to achieve the desired gear ratio. Here are the key steps involved:

- Clutch Engagement:

To shift to a higher gear ratio, the clutch associated with the gear component that needs to be engaged is activated. The clutch connects the rotating member, such as the sun gear, planet carrier, or ring gear, to the stationary member, allowing torque transmission. This engagement results in a change in the gear ratio, leading to higher speed or torque output depending on the specific gear set configuration.

- Brake Application:

On the other hand, to shift to a lower gear ratio, a brake associated with the gear component that needs to be disengaged is applied. The brake immobilizes or slows down the rotation of the selected gear element, preventing it from transmitting torque. By selectively braking certain components, the gear ratio is altered, resulting in a lower speed or higher torque output.

- Sequential Shifting:

In some planetary gear systems, gear shifting is performed sequentially. This means that one gear component is engaged or disengaged at a time, gradually transitioning from one gear ratio to another. Sequential shifting allows for smooth and controlled gear changes, minimizing the stress on the transmission components and ensuring seamless power transmission.

- Electronic Control:

In modern applications, gear shifting in planetary gear systems is often electronically controlled. Electronic control systems utilize sensors, actuators, and a control unit to monitor various parameters such as vehicle speed, engine load, and driver input. Based on these inputs, the control unit determines the optimal gear shift points and actuates the clutches and brakes accordingly. Electronic control enhances the efficiency, precision, and automation of the gear shifting process.

In summary, gear shifting in planetary gear systems involves the engagement and disengagement of clutches and brakes to alter the gear ratio. By selectively connecting or disconnecting specific gear components, the speed and torque output can be adjusted. Sequential shifting and electronic control systems further enhance the gear shifting process, providing smooth and efficient operation in various applications, including automotive transmissions and industrial machinery.

How do planetary gears differ from other types of gear arrangements?

Planetary gears, also known as epicyclic gears, possess unique characteristics and differ from other types of gear arrangements in several ways. Let’s explore the distinguishing features of planetary gears:

- Internal Gear Meshing:

Unlike other gear arrangements where the gears typically mesh externally, planetary gears have internal gear meshing. This means that the gear teeth of the sun gear, planet gears, and ring gear are located on the inside surfaces, allowing for compact and space-efficient designs.

- Multiple Gear Sets:

Planetary gear systems consist of multiple gear sets working in parallel or series. These gear sets include the sun gear, planet gears, and ring gear. By combining and configuring these gear sets, different gear ratios and torque distributions can be achieved, providing versatility and flexibility in various applications.

- Central Sun Gear:

A distinctive feature of planetary gears is the presence of a central sun gear. The sun gear is typically driven by an input source, such as a motor or engine. It is located at the center of the gear arrangement and serves as the primary driver for overall gear operation.

- Orbiting Planet Gears:

In planetary gears, the planet gears rotate on their own axes while simultaneously orbiting around the sun gear. This combination of rotational and orbital movement allows for efficient torque transmission and enables the gear arrangement to achieve different gear ratios based on the relative sizes and positions of the gears.

- Compact Size:

One of the key advantages of planetary gears is their compact size. The internal gear meshing and the arrangement of multiple gear sets within a single gear system contribute to their space-saving design. This makes planetary gears suitable for applications where size and weight restrictions are important considerations.

- Wide Range of Applications:

Planetary gears find applications in various industries and mechanical systems. They are commonly used in automotive transmissions, industrial machinery, robotics, aerospace systems, and more. Their ability to achieve different gear ratios, transmit torque efficiently, and operate in compact spaces makes them versatile solutions in diverse engineering applications.

In summary, planetary gears differ from other types of gear arrangements due to their internal gear meshing, multiple gear sets, central sun gear, orbiting planet gears, compact size, and wide range of applications. These characteristics make planetary gears suitable for achieving various gear ratios, transmitting torque efficiently, and meeting the space requirements of different mechanical systems.

editor by CX 2023-11-06

China best Flange Mounted Planetary Gearbox Reduction Gear Pad Series manufacturer

Product Description

|

Model |

PAD064 |

|

Ratio |

70 |

|

Backlash |

P2 ( ≤8arcmin ) |

|

Rated Output Torque |

50 Nm |

|

Rated Input Speed |

5000 rpm |

|

Effciency |

≥97% |

|

Torsional Rigidity |

13 |

|

Lubrication |

Synthetic Grease |

|

Operating Temperature |

-15ºC~+90ºC |

|

Protection Temperature |

IP65 |

|

Mounting Position |

Any Direction |

|

Service Life |

22000 hours |

- Overview of PAD Planetary Gearbox

* PAD series features of high precision and low backlash

* 3F PAD series adopts integral ball bearings to realize high rigidity and high torque

* Due to the use of tapered needle roller bearing, it achieve the high load capacity.

* The PAD Speed reducer can be matched with any brands of motors.

* Free maintenance and long service life

Product Parameters

Detailed Photos

14 types of speed building ratio:=4-100

Minimum return interval: P0, P1P2

Maximum output torque: 23N. m-650N. m

Extremely high torsional rigidity and excellent performance

The highest load free policy is used in conditions with extremely high bearing capacity

Optimize power transmission and increase efficiency line by 98%

Very quiet during operation

Lifetime lubrication, no push protection

Fully sealed, IP65 protection level

Shortest structure and flexible installation

Small model: 64.90.110.140

Application

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

Certifications

Packaging & Shipping

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

How do planetary gears handle changes in speed and torque distribution?

Planetary gears are capable of effectively handling changes in speed and torque distribution due to their unique design and configuration. Let’s explore how planetary gears handle these changes:

- Speed Changes:

Planetary gears can handle speed changes by utilizing the different gear ratios they offer. By adjusting the sizes and numbers of teeth on the sun gear, planet gears, and ring gear, different gear ratios can be achieved. When the input speed is applied to the sun gear, it gets transmitted to the planet gears, resulting in a specific output speed. By changing the gear ratio, the output speed can be adjusted accordingly. This ability to vary the gear ratio allows planetary gears to adapt to different speed requirements in mechanical systems.

- Torque Distribution:

Planetary gears excel in distributing torque across multiple gear teeth, ensuring efficient torque transmission and load sharing. The planet gears are meshed with both the sun gear and the ring gear, enabling torque to be transmitted through multiple contact points simultaneously. This distributed torque distribution helps in reducing stress on individual gear teeth and enhances the overall torque-carrying capacity of the gear system. The load is shared among the planet gears, preventing excessive wear and minimizing the risk of gear failure.

- Torque Amplification:

Planetary gears can also handle torque amplification, allowing for increased torque output compared to the input torque. By fixing the ring gear and inputting power to the sun gear, the planet gears rotate and contribute to multiplying the torque. The arrangement of multiple gear sets in a compact design enables torque amplification, making planetary gears suitable for applications that require high torque output while maintaining a smaller physical size.

- Load Balancing:

Another aspect of torque distribution in planetary gears is load balancing. The planet gears distribute the load across multiple gear teeth, reducing the concentration of forces on individual teeth. This load balancing capability results in improved gear system durability and longevity. It also helps in minimizing vibration, noise, and wear, ensuring smoother and more reliable operation.

- Flexible Configuration:

Planetary gears offer flexibility in their configuration, allowing for the accommodation of changes in speed and torque distribution. The number of planet gears, the size of the gears, and their arrangement can be adjusted to meet specific application requirements. This flexibility enables planetary gears to handle a wide range of speed and torque variations, making them adaptable to different mechanical setups.

In summary, planetary gears handle changes in speed and torque distribution through their ability to adjust gear ratios, distribute torque across multiple gear teeth, amplify torque, balance loads, and accommodate flexible configurations. These characteristics make planetary gears suitable for applications that require precise control over speed and torque, efficient power transmission, and reliable performance.

How do planetary gears handle variations in tooth engagement during operation?

Planetary gears are designed to handle variations in tooth engagement during operation, ensuring smooth and reliable performance. Let’s explore how planetary gears address these variations:

- Tolerance for Misalignment:

Planetary gears are designed with a certain degree of tolerance for misalignment. This means that slight variations in tooth engagement due to manufacturing tolerances, assembly, or operating conditions are accommodated without causing significant impact on the gear system. The gear teeth are carefully designed with appropriate profiles, clearances, and backlash to allow for some degree of misalignment while maintaining proper functioning.

- Load Distribution:

The arrangement of multiple planet gears in a planetary gear system helps distribute the load across multiple gear teeth. Each planet gear shares the load with the adjacent gears, reducing the stress on individual teeth and promoting even tooth engagement. This load distribution capability helps minimize localized wear, noise, and vibration, resulting in smoother and more efficient operation.

- Flexible Mounting and Support:

Planetary gears are often mounted on flexible support structures, such as bearings or flexible couplings. These components help absorb and compensate for small variations in tooth engagement during operation. The flexible mounting and support systems provide some degree of flexibility and compliance, allowing the gears to self-adjust and maintain proper tooth contact under varying operating conditions.

- Lubrication and Cooling:

Proper lubrication and cooling play a crucial role in handling variations in tooth engagement. Lubricants reduce friction and wear between gear teeth, ensuring smooth operation and minimizing the impact of tooth engagement variations. Additionally, effective cooling mechanisms help dissipate heat generated during operation, preventing excessive temperature rise that could affect the gear meshing performance.

- Robust Construction:

Planetary gears are typically constructed using high-strength materials and precise manufacturing techniques. This robust construction enhances the gear system’s ability to withstand variations in tooth engagement. By ensuring high-quality gear components, proper heat treatment, and stringent quality control, planetary gears are built to handle the dynamic loads and variations encountered during operation.

In summary, planetary gears handle variations in tooth engagement through their tolerance for misalignment, load distribution among multiple planet gears, flexible mounting and support, effective lubrication and cooling, and robust construction. These design considerations and features enable planetary gears to maintain proper tooth contact, minimize wear and noise, and ensure reliable performance in various applications, including automotive transmissions, industrial machinery, and power transmission systems.

How do planetary gears contribute to power transmission and gear reduction?

Planetary gears play a significant role in power transmission and gear reduction. Let’s explore how planetary gears contribute to these aspects:

- Torque Amplification:

One of the key contributions of planetary gears is torque amplification. The arrangement of multiple gear sets in a compact design allows for torque multiplication. When the input power is applied to the sun gear, it drives the rotation of the planet gears. The planet gears, in turn, mesh with the ring gear, creating a mechanical advantage that amplifies the torque output. This torque amplification is beneficial in applications where high torque is required while maintaining a smaller form factor.

- Gear Ratio Variation:

Another contribution of planetary gears is their ability to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. This flexibility in gear ratios allows machinery to adapt to varying speed and torque requirements, enabling precise control and efficient power transmission.

- Gear Reduction:

Planetary gears are commonly used for gear reduction applications. Gear reduction refers to the process of reducing the rotational speed and increasing the torque output of a power source. In a planetary gear system, gear reduction is achieved by fixing the ring gear and allowing the sun gear to rotate as the input. The rotation of the sun gear drives the planet gears, which in turn rotate the output carrier or arm. The output speed is slower than the input speed, resulting in gear reduction. This gear reduction capability is valuable in various applications, such as automotive transmissions and power transmission systems.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. The load is shared among the planet gears, allowing for higher torque capacity and reduced wear on individual gear teeth. This efficient power transmission ensures that a significant portion of the input power is effectively transmitted to the output, making planetary gears suitable for applications where energy conservation and optimization are crucial.

In summary, planetary gears contribute to power transmission and gear reduction through torque amplification, gear ratio variation, gear reduction mechanism, and efficient power transmission. The ability to amplify torque, achieve different gear ratios, and transmit power efficiently makes planetary gears widely used in various industries and mechanical systems.

editor by CX 2023-11-03

China high quality Mc Plastic Planetary Transmission Spur Gears/Plastic Gear Set /Plastic Spur Gears/Large Plastic Gears/Plastic Cogs/Gears for Sale/Plastic Miter Gears/Gear with high quality

Product Description

With a capable machining team and comprehensive knowledge of materials, advanced machineries and facilities, Energetic Industry served clients in broad field.

We can produce precision machining parts according to your idea, not only for material choosing, but also property requirements and shapes.

1. Customized material

| Materials Available | General Plastic: HDPE, PP, PVC, ABS, PMMA(Acrylic) ect. |

| Engineering Plastic: POM, PA6, MC nylon, Nylon 66, PTFE, UHMWPE,PVDF ect. | |

| High Performance Plastic: PPS, PEEK, PI, PEI ect. | |

| Thermosetting Plastic: Durostone, Ricocel sheet, G10, FR4, Bakelite ect. | |

| Spcial Plastic Material: Plastic +GF/CA/Oil/Brone/Graphit/MSO2/ceramic ect. | |

| Spcial Plastic Plastic Alloy: PE+PA, PP+PA, POM + PTFE ect. | |

| Metals: Carbon Steel, SS Steel, Brass, Iron, Bronze, Aluminum, Titanium | |

| Special parts: Metal + Plastic Combined Part |

2. Customized property

ESD, conductive, hardness, wear resistance, fire-resistant, corrosion resistance, impact strength, work temperature, UV resistant ect.

3. Customized shape with drawing

Gear, rollers, wheels, base part, spacers, blade, liner, rack, bearings, pulley, bearing sleeves, linear guide rail, sliding block, guide channel, spiral, washer, positioning strip, joint, sheath, CHINAMFG plate, retaining ring, slot, skating board, frame, cavity parts, CHINAMFG jig and fixture, PCB solder pallet, profiles.

Molds, cavity, Radiator fin, prototype, outermost shell, fittings and connectors, screws , bolt …

Further services of CNC machining:

Processing: Cutting, CNC machining, CNC milling and turning, drilling, grinding, bending, stamping, tapping, injection

Surface finish: Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated

Application Field:

- Electronic and electrician

- Physical and Electronic Science Research

- Mineral and coal

- Aerospace

- Food processing

- Textile printing & dyeing industry

- Analytical instrument industry

- Medical device industry

- Semi conductor, solar, FPD industry

- Automotive industry

- Oil & Gas

- Automobile

- Machinery and other industrial ect.

| Material: | PA |

|---|---|

| Color: | Natural, Black, Red, Green, Customized |

| Processing: | CNC Machining |

| Packing: | Thick Carton Boxes |

| Outstanding Property: | Good Wear Resistant |

| Production Time: | 3~25 Days |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in automotive applications?

Planetary gears are widely used in various automotive applications due to their numerous advantages. Let’s explore how planetary gears can be utilized in the automotive industry:

- Automatic Transmissions:

One of the primary applications of planetary gears in automobiles is in automatic transmissions. Automatic transmissions use a combination of planetary gear sets to achieve different gear ratios, allowing for smooth and efficient shifting between gears. The compact size and high torque capacity of planetary gears make them well-suited for this purpose, providing reliable and efficient power transmission in vehicles.

- Four-Wheel Drive Systems:

Planetary gears are also employed in four-wheel drive systems, where they help distribute power between the front and rear wheels. By utilizing planetary gear arrangements, the torque can be split between the front and rear axles, providing improved traction and stability on various road conditions. This allows vehicles to have enhanced off-road capabilities and better performance in challenging driving situations.

- Hybrid and Electric Vehicles: