Product Description

Swing Motor CX210B Planetary Sun Gear SM 2nd KRC10560 LCA1 9571B 16571A1 9571B 16 0571 A1 CX130 16571A1 CX A1 9571B 161323A1 9030 155826A1 9030B 160560A1 CX210 431853A1 CX210B KRC1571 CX290 KSC5710 CX330 KSC5717

Hyundai

R180LC-3 RG08S-172-01 R2 EC210 7118-35710 EC210B 14541069 EC330 1055-0571 EC330B 1055-0571 EC360 1055-0571 EC360B 1055-0571

Sumitomo

SH120 KNC0087 SH200-5 KRC1571 SH300A-5 KSC5717

Kato

HD700SEV HD800V2 HD820-II

JCB

JS130 KNC0051 JS130 LNM571 LS-2650C-II KNC0037 2650Q KNC0051 2650Q LNM571 130LX KMC0078 130LX LNM571 2700Q LNM0449

CAT

312B 114-8226 320B 320C 148-4644 320L 7Y-1566 322C 191-2693 324D 325C 325B 110-7215 325D 329D 330B 114-1305 330C 330D 330L 199-4539 345D 296-6249

Kobelco

SK60V YRW00002F1 SK70SR YT32W00002F1 SK80CS YT32W00002F2 SK115SR YX32W00002F1 SK135SR YX32W00002F2 SK135SR-2 YY32W00004F1 SK200-8 YN32W00571F2 SK210-6 YN32W00571F1 SK330-6 LC32W00011F1 SK350-8 LC32W00011F1

Komatsu

PC60-5-6-7, PC100, PC120-5-6-7, PC130-5-6-7, PC150-6, PC160, PC180, PC200-1-3-5-6-7, PC200LC-7, PC210LC-6, PC220-1-3-5, PC220-7, PC228, PC250-6, PC270LC-6, PC280, PC300-3-5-6-7, PC350, PC4001-3-5

Hitachi

EX40, EX60, EX150, EX100M, EX100, EX120, EX150, EX200-1-2-3, EX300-1-3-5, EX400, UH08, UH07 ZX55 ZX60 ZX70 ZX110 ZX120 ZX130 ZX160 ZX200 ZX210 ZX240 ZX270 ZX330 ZX350 ZX450

Parts Details

Our Advantages

Main Products

| Brand: | Komatsu , , CHINAMFG , Vol Vo , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG , CHINAMFG 3CX 4CX Backhoe Loader |

| egory: | Spare Parts: |

| Advantaged Products: | Excavator Hydraulic Pump , Swing Motor Assy , Travel Motor Assy , Turbocharger , Water Pump , Main&Relief Valve Group … |

| Electrical Parts: | Excavator Solenoid Valve , Sensor , Switch , Controller , Monitor , Accelerator , Stater Motor , Alternator , Wipper Motor , Lamp , Water Tank …. |

| Engine Parts: | Excavator Engine Assy , Cylinder Head , Cylinder Block , Crankshaft , Camshaft , Linner Kits ( Piston / Piston Ring / Linner / Bearing ) , Gasket Kits , Overhaul Kits , Connecting Rod , Valve , Injector… |

| Cooling Parts: | Excavator Hydraulic Oil Cooler , Radiator , Oil Cooler Cover , Oil Cooler Assy , Fan , Blower Motor, EGR Pipe , Valve Chamber Cover… |

| Rubber Parts: | Excavator O-Ring , Seal Kits , Floor Mate Rubber , Coupling , Engine Belt , Belt Tensioner… |

| Hose & Harness Parts: | Excavator Pipe In , Manifold Exhaust , Water Hose , Oil Tube , Cabin Harness , Engine Harness… |

| Filtering Parts: | Excavator Oil Filter , Fuel Filter , Air Filter , Oil Separator , Air Filter Cover … |

Customer high Praise

Company Profile

Xihu (West Lake) Dis.an Machine Equipment Co., Ltd.( KOKO SHOP)

HangZhou Xihu (West Lake) Dis.an Machinery Equipment Co., Ltd. Our company was established in 2011.

Xihu (West Lake) Dis.an is a professional spare parts manufacturer and reliable supplier, providing almost all spare parts for various models rock breakers.

Specializes in:

Excavator accessories

Hydraulic breaker accessories

Breaker Spare Parts Suitable for the brands: SOOSAN, FURUKAWA, KRUPP, ATLAS-COPCO, EDT, JCB, NPK, , HANWOO, TOKU, FINE, OKADA, XIHU (WEST LAKE) DIS., MONTABERT, INDECO, KWANGLIM, RAMMER, KONAN, KOMATSU, GENERAL etc. Excavator Spare Parts Suitable for the brands: CATEE, KOMATSU, HITACHI, VOLVO, KOBELCO, CASE, SUMITOMO, DOOSA, NHYUNDAI, SANY, XG ect. The logistics in HangZhou is very convenient that we deliver goods to the whole world.

| After-sales Service: | Online |

|---|---|

| Warranty: | Online |

| Type: | Wheel Excavator |

| Usage: | Special Excavator, Marine Excavator, Mining Excavator, GM Excavator |

| Bucket: | Backhoe |

| Transmission: | Hydraulic Transmission |

| Customization: |

Available

| Customized Request |

|---|

Can planetary gears be used in automotive applications?

Planetary gears are widely used in various automotive applications due to their numerous advantages. Let’s explore how planetary gears can be utilized in the automotive industry:

- Automatic Transmissions:

One of the primary applications of planetary gears in automobiles is in automatic transmissions. Automatic transmissions use a combination of planetary gear sets to achieve different gear ratios, allowing for smooth and efficient shifting between gears. The compact size and high torque capacity of planetary gears make them well-suited for this purpose, providing reliable and efficient power transmission in vehicles.

- Four-Wheel Drive Systems:

Planetary gears are also employed in four-wheel drive systems, where they help distribute power between the front and rear wheels. By utilizing planetary gear arrangements, the torque can be split between the front and rear axles, providing improved traction and stability on various road conditions. This allows vehicles to have enhanced off-road capabilities and better performance in challenging driving situations.

- Hybrid and Electric Vehicles:

Planetary gears play a crucial role in hybrid and electric vehicle powertrains. In these vehicles, planetary gear sets are often used to combine the power from the internal combustion engine and the electric motor. The gear arrangement allows for seamless transitions between different power sources, enabling efficient energy management and optimized performance.

- Start-Stop Systems:

Start-stop systems, which automatically shut off the engine when the vehicle is stationary and restart it when needed, often incorporate planetary gears. These gears help engage and disengage the engine from the drivetrain smoothly, ensuring a quick and seamless transition between the engine’s off and on states. Planetary gears contribute to the overall efficiency and reliability of start-stop systems.

- Power Steering:

Some power steering systems in automobiles utilize planetary gears to provide assistance in steering. These gears help amplify the driver’s input torque, making steering easier and more responsive. The compact size and high torque capacity of planetary gears make them suitable for power steering applications.

In summary, planetary gears find extensive use in automotive applications, including automatic transmissions, four-wheel drive systems, hybrid and electric vehicle powertrains, start-stop systems, and power steering. Their compact size, high torque capacity, and ability to achieve multiple gear ratios make them well-suited for these applications, providing efficient power transmission, improved performance, and enhanced driving experience in vehicles.

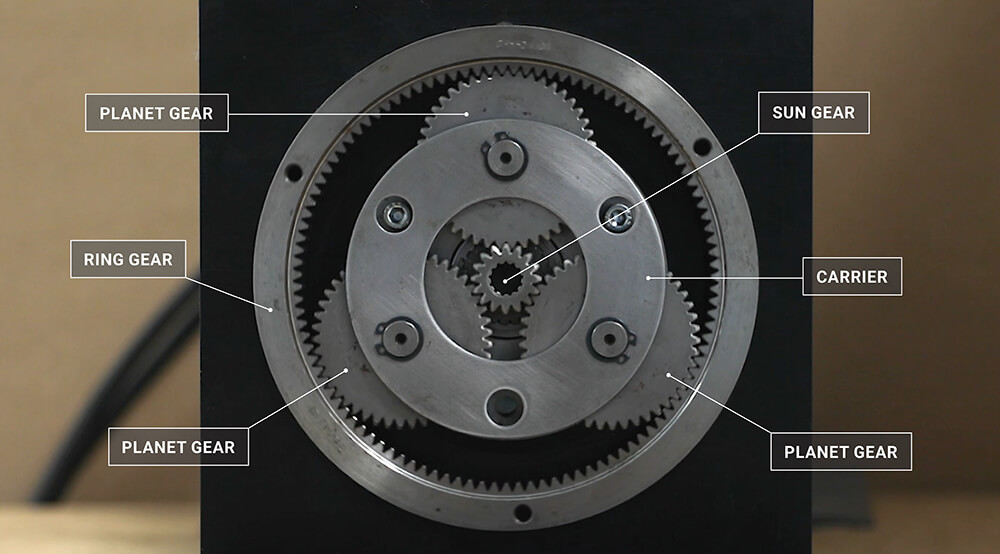

How do planetary gears handle variations in direction and torque transmission?

Planetary gears are versatile mechanisms that can effectively handle variations in direction and torque transmission. Let’s explore how they achieve this:

- Direction Reversal:

Planetary gears are capable of transmitting torque in both forward and reverse directions. By changing the input and output connections, the direction of rotation can be reversed without the need for additional components or complex mechanisms. This makes planetary gears well-suited for applications where frequent changes in direction are required, such as automotive transmissions.

- Torque Amplification and Reduction:

One of the notable characteristics of planetary gears is their ability to amplify or reduce torque depending on the arrangement of gear components. Let’s consider a basic arrangement with a sun gear, planet gears, and a ring gear:

- Torque Amplification:

When the sun gear is the input and the ring gear is the output, the planet gears rotate on their own axes while also revolving around the sun gear. This arrangement allows for torque amplification, meaning the output torque can be higher than the input torque. This is particularly useful in applications where higher torque is required, such as heavy machinery or power transmission systems.

- Torque Reduction:

Conversely, by fixing the ring gear and using the sun gear as the output, the planet gears rotate on their own axes while also revolving around the fixed ring gear. In this configuration, the output torque is lower than the input torque, enabling torque reduction. This can be advantageous in applications where torque needs to be reduced, such as speed reduction systems or precision machinery.

- Combination of Gear Stages:

Planetary gears can be combined into multiple stages, with each stage having its own set of sun gears, planet gears, and ring gears. This arrangement allows for further variations in torque transmission. By connecting the output of one stage to the input of another, the torque can be further amplified or reduced, providing flexibility in power transmission systems.

- Custom Gear Ratios:

By selecting the appropriate sizes and numbers of teeth for the sun gears, planet gears, and ring gears, custom gear ratios can be achieved in planetary gear systems. This allows for precise control over torque transmission and enables the adaptation of the gear arrangement to specific application requirements.

In summary, planetary gears handle variations in direction and torque transmission through their ability to reverse direction without additional components, torque amplification or reduction based on gear arrangement, combination of multiple gear stages, and the ability to achieve custom gear ratios. These features make planetary gears a versatile choice for a wide range of applications requiring efficient and flexible power transmission.

How do planetary gears contribute to power transmission and gear reduction?

Planetary gears play a significant role in power transmission and gear reduction. Let’s explore how planetary gears contribute to these aspects:

- Torque Amplification:

One of the key contributions of planetary gears is torque amplification. The arrangement of multiple gear sets in a compact design allows for torque multiplication. When the input power is applied to the sun gear, it drives the rotation of the planet gears. The planet gears, in turn, mesh with the ring gear, creating a mechanical advantage that amplifies the torque output. This torque amplification is beneficial in applications where high torque is required while maintaining a smaller form factor.

- Gear Ratio Variation:

Another contribution of planetary gears is their ability to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. This flexibility in gear ratios allows machinery to adapt to varying speed and torque requirements, enabling precise control and efficient power transmission.

- Gear Reduction:

Planetary gears are commonly used for gear reduction applications. Gear reduction refers to the process of reducing the rotational speed and increasing the torque output of a power source. In a planetary gear system, gear reduction is achieved by fixing the ring gear and allowing the sun gear to rotate as the input. The rotation of the sun gear drives the planet gears, which in turn rotate the output carrier or arm. The output speed is slower than the input speed, resulting in gear reduction. This gear reduction capability is valuable in various applications, such as automotive transmissions and power transmission systems.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. The load is shared among the planet gears, allowing for higher torque capacity and reduced wear on individual gear teeth. This efficient power transmission ensures that a significant portion of the input power is effectively transmitted to the output, making planetary gears suitable for applications where energy conservation and optimization are crucial.

In summary, planetary gears contribute to power transmission and gear reduction through torque amplification, gear ratio variation, gear reduction mechanism, and efficient power transmission. The ability to amplify torque, achieve different gear ratios, and transmit power efficiently makes planetary gears widely used in various industries and mechanical systems.

editor by CX 2023-11-03