Product Description

Excellent powder metallurgy parts metallic sintered parts

We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to customer’s requirement to make it. if you are interested in our product, please do not hesitate to contact us, we would like to offer the top quality and best service for you. thank you!

How do We Work with Our Clients

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don’t even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

| Place of origin: | Jangsu,China |

| Type: | Powder metallurgy sintering |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron,stainless,steel,copper |

| Key selling points: | Quality assurance |

| Mould type: | Tungsten steel |

| Material standard: | MPIF 35,DIN 3571,JIS Z 2550 |

| Application: | Small home appliances,Lockset,Electric tool, automobile, |

| Brand Name: | OEM SERVICE |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgr,CNC Machining |

| Powder Metallurgr: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

The Advantage of Powder Metallurgy Process

1. Cost effective

The final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .

2. Complex shapes

Powder metallurgy allows to obtain complex shapes directly from the compacting tooling ,without any machining operation ,like teeth ,splines ,profiles ,frontal geometries etc.

3. High precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered,improvable up to IT 5-7 after sizing .Additional machining operations can improve the precision .

4. Self-lubrication

The interconnected porosity of the material can be filled with oils ,obtaining then a self-lubricating bearing :the oil provides constant lubrication between bearing and shaft ,and the system does not need any additional external lubricant .

5. Green technology

The manufacturing process of sintered components is certified as ecological ,because the material waste is very low ,the product is recyclable ,and the energy efficiency is good because the material is not molten.

FAQ

Q1: What is the type of payment?

A: Usually you should prepay 50% of the total amount. The balance should be pay off before shipment.

Q2: How to guarantee the high quality?

A: 100% inspection. We have Carl Zeiss high-precision testing equipment and testing department to make sure every product of size,appearance and pressure test are good.

Q3: How long will you give me the reply?

A: we will contact you in 12 hours as soon as we can.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q7: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, as Required |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Sintered Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | as Required |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

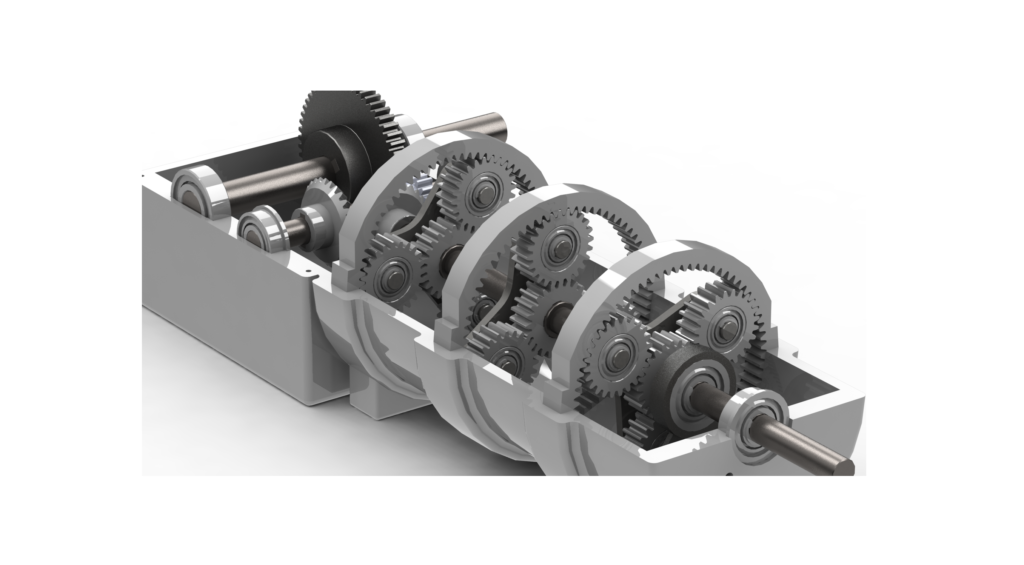

How does a planetary gear arrangement handle variations in load and stress?

A planetary gear arrangement offers inherent advantages in handling variations in load and stress. Let’s explore how it achieves this:

- Distributed Load:

One of the key advantages of a planetary gear arrangement is its ability to distribute the load among multiple gears. In this arrangement, the load is shared by the sun gear, planet gears, and ring gear, with each gear sharing a portion of the total load. As a result, the load on each individual gear is reduced compared to a single gear system, reducing stress concentration and enhancing the overall load-carrying capacity.

- Load Sharing:

Planet gears in a planetary gear system share the load as they are meshed with both the sun gear and the ring gear. This load-sharing characteristic ensures that the load is distributed evenly across multiple gear teeth and contact points. Consequently, the stress on each gear is reduced, minimizing the risk of tooth failure and increasing the system’s durability.

- Torque Splitting:

In a planetary gear arrangement, torque can be split among multiple paths. By controlling the distribution of torque between the sun gear and ring gear, variations in load can be managed effectively. If one gear path experiences higher stress, the torque distribution can be adjusted to shift the load to other gear paths, thereby balancing the stress and minimizing the risk of gear failure.

- Multiple Stages:

Planetary gear arrangements can be designed with multiple stages, involving multiple sets of sun gears, planet gears, and ring gears. Each stage can handle a portion of the load, allowing for further load distribution and stress reduction. This multi-stage configuration enhances the gear arrangement’s capacity to handle variations in load and stress, making it suitable for demanding applications.

- Robust Construction:

Planetary gear systems are known for their robust construction and high torque capacity. They are designed to withstand heavy loads and resist the effects of stress concentration. The use of high-quality materials and precise manufacturing techniques further enhances their ability to handle variations in load and stress.

In summary, a planetary gear arrangement handles variations in load and stress through distributed load sharing, torque splitting, multiple stages, and robust construction. By distributing the load among multiple gears, sharing the load between different paths, and employing multiple gear stages, a planetary gear arrangement can effectively manage variations in load and stress, ensuring reliable and durable operation in a wide range of applications.

Can planetary gears be used in aerospace and aviation applications?

Planetary gears find extensive use in aerospace and aviation applications due to their unique characteristics and advantages. Let’s explore how planetary gears can be utilized in the aerospace and aviation industry:

- Aircraft Engines:

Planetary gears play a crucial role in aircraft engines, especially in the reduction gearbox. The reduction gearbox connects the high-speed turbine shaft with the low-speed propeller shaft, allowing efficient power transmission while maintaining optimal propeller speed. Planetary gears within the reduction gearbox help achieve the required gear ratios and torque conversion, ensuring smooth and reliable engine operation.

- Landing Gear Systems:

Planetary gears are also utilized in landing gear systems of aircraft. These gears provide the necessary torque and force to retract and extend the landing gear during takeoff and landing. Planetary gears offer compactness, high torque capacity, and the ability to handle heavy loads, making them suitable for this critical application.

- Actuation Systems:

Actuation systems in aerospace and aviation, such as those used for flight control surfaces, also benefit from the use of planetary gears. These gears enable precise and reliable movement of control surfaces, such as ailerons, elevators, and rudders. Planetary gears’ ability to handle high torques, provide accurate positioning, and withstand varying loads makes them well-suited for actuation systems.

- Satellite and Spacecraft Mechanisms:

In satellite and spacecraft applications, planetary gears are utilized in various mechanisms. They can be found in solar array drives, antenna pointing systems, and deployment mechanisms for scientific instruments. Planetary gears offer compactness, high torque transmission, and the ability to handle the extreme conditions of space environments.

- Auxiliary Power Units (APUs):

APUs in aircraft are responsible for providing auxiliary power during ground operations and in-flight emergencies. Planetary gears are often employed in APU systems to transfer power from the engine to the auxiliary systems, such as electrical generators or hydraulic pumps. These gears ensure efficient power transmission and reliable operation of the APU.

In summary, planetary gears have significant applications in aerospace and aviation. They are utilized in aircraft engines, landing gear systems, actuation systems, satellite and spacecraft mechanisms, as well as auxiliary power units. The compact size, high torque capacity, precise positioning, and reliable operation of planetary gears make them well-suited for these critical applications in the aerospace and aviation industry.

What industries commonly use planetary gears in their applications?

Planetary gears find applications in a wide range of industries and mechanical systems. Let’s explore some of the industries that commonly utilize planetary gears:

- Automotive Industry:

The automotive industry extensively uses planetary gears in various applications. Planetary gears are commonly found in automatic transmissions, where they enable smooth gear shifting, provide different gear ratios, and transmit torque efficiently. They are also used in differential systems, allowing wheels to rotate at different speeds while maintaining power distribution.

- Robotics and Automation:

Planetary gears play a crucial role in robotics and automation systems. They are employed in robotic joints and actuators to provide precise motion control, compact size, and high torque transmission. Planetary gears enable robotic arms to move accurately and handle heavy loads, making them essential components in industrial robots and robotic manipulators.

- Aerospace and Aviation:

The aerospace and aviation industries utilize planetary gears in various applications. They are used in aircraft landing gear systems, where they provide reliable torque transmission and compact design. Planetary gears are also employed in aircraft engine systems, helicopter rotor systems, and satellite mechanisms due to their efficiency, high torque capacity, and ability to operate in space-restricted environments.

- Power Generation:

Planetary gears are utilized in power generation equipment, including wind turbines and hydroelectric generators. In wind turbines, planetary gears enable the conversion of low-speed rotor rotation to high-speed generator rotation, ensuring efficient power generation. They are also employed in hydroelectric generators to transmit power from turbines to electrical generators, providing gear reduction and torque amplification.

- Industrial Machinery:

Planetary gears are widely used in industrial machinery applications. They are found in heavy-duty machinery such as mining equipment, construction machinery, and material handling systems. Planetary gears provide high torque transmission, compactness, and durability, making them suitable for handling demanding tasks in industrial environments.

- Marine and Shipbuilding:

The marine and shipbuilding industries employ planetary gears in various marine propulsion systems. They are used in marine engines, propeller systems, and thrusters. Planetary gears provide efficient power transmission, speed control, and compact design for propulsion systems in vessels ranging from small boats to large ships.

- Medical Equipment:

In the medical field, planetary gears are utilized in various equipment and devices. They are found in medical imaging systems like CT scanners and MRI machines, providing precise motion control and reducing image distortion. Planetary gears are also used in surgical robots and medical devices that require compact size, high torque, and accurate positioning.

These are just a few examples of the industries that commonly use planetary gears in their applications. The versatility, efficiency, and compactness of planetary gears make them suitable for a broad range of industries where precise motion control, torque transmission, and space-saving design are essential requirements.

editor by CX 2023-09-11